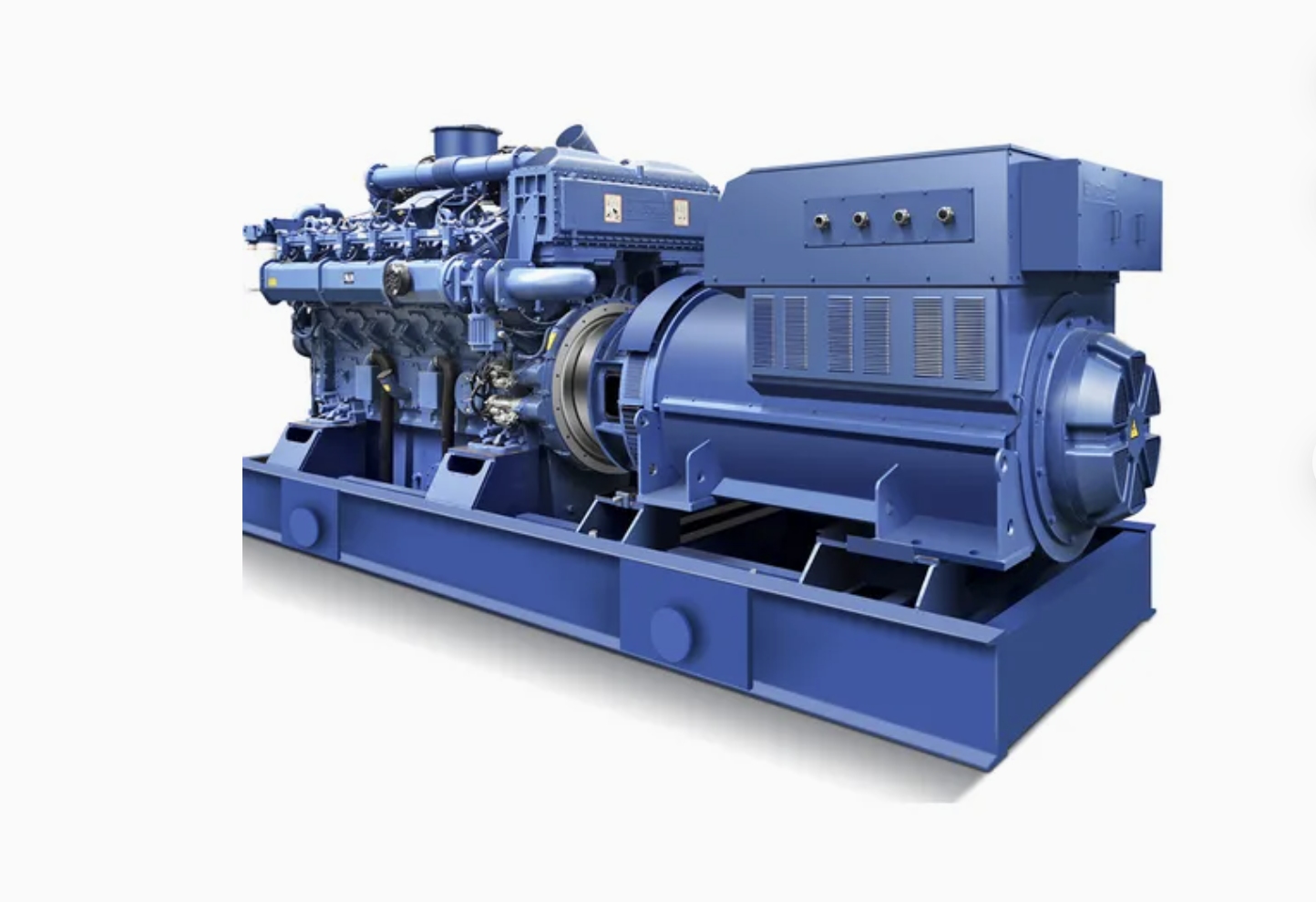

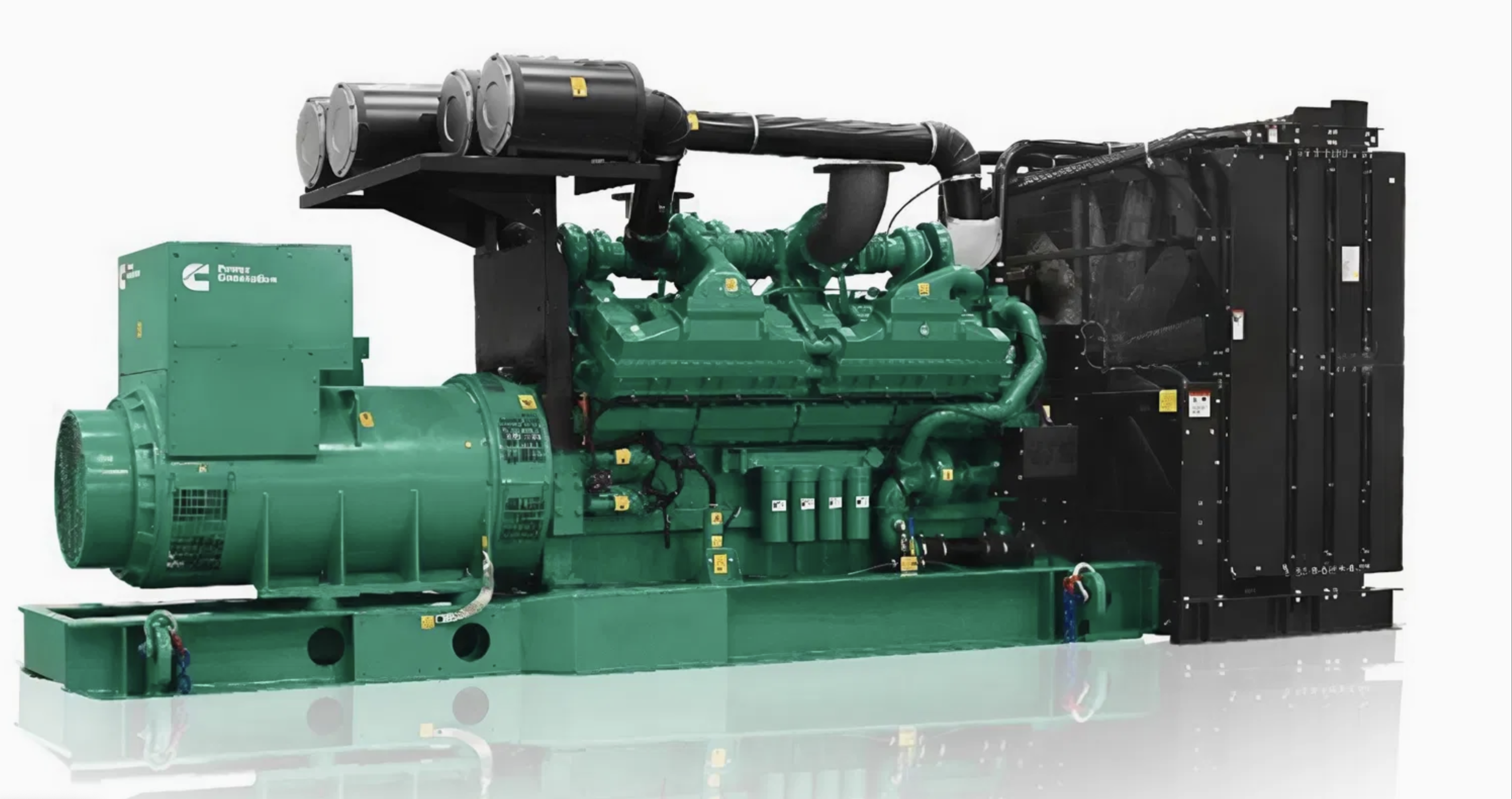

genset gas engine

A genset gas engine is a sophisticated power generation system designed to convert natural gas or other gaseous fuels into electrical energy. This advanced piece of machinery combines the reliability of traditional combustion engines with the environmental benefits of gas-powered systems. At its core, the genset gas engine features a robust internal combustion mechanism optimized for gaseous fuel operation, coupled with an electrical generator that transforms mechanical energy into usable electricity. The engine's design incorporates precise fuel delivery systems, advanced ignition controls, and sophisticated thermal management components to ensure optimal performance and efficiency. These units are engineered to deliver consistent power output while maintaining low emission levels, making them ideal for various applications including industrial facilities, commercial buildings, and distributed power generation systems. The technology encompasses multiple subsystems working in harmony, including fuel management, cooling systems, and electronic control units that monitor and adjust operating parameters in real-time. Modern genset gas engines are equipped with smart monitoring capabilities, allowing for predictive maintenance and remote operation management. Their versatility extends to various power output ranges, typically from hundreds of kilowatts to several megawatts, making them suitable for diverse scale applications.