ການເຂົ້າໃຈການຄິດໄລ່ເວລາໃຊ້ງານຂອງເຄື່ອງປັ່ນໄຟຟ້າສຳລັບລະບົບພະລັງງານ Cummins

ເມື່ອລົງທຶນໃນວິທີການສະຫນອງພະລັງງານສຳຮອງ, ປັດໄຈໜຶ່ງທີ່ສຳຄັນທີ່ສຸດທີ່ຕ້ອງພິຈາລະນາແມ່ນ ເວລາທີ່ເຄື່ອງປັ່ນໄຟຂອງທ່ານສາມາດດຳເນີນການໄດ້ຕາມປະລິມານເຊື້ອໄຟໃຫ້. ສຳລັບ ເຄື່ອງຜະລິດ Cummins ຊุด, ການກຳນົດເວລາດຳເນີນງານດ້ວຍເຊື້ອໄຟ 100 ແກລອນ ຕ້ອງການຄວາມເຂົ້າໃຈໃນໂຕປ່ຽນແປງຕົ້ນຕໍຫຼາຍຢ່າງທີ່ມີຜົນກະທົບຕໍ່ການບໍລິໂภກນ້ຳມັນ. ຄູ່ມືລະອຽດນີ້ຈະສຳຫຼວດປັດໄຈຕ່າງໆທີ່ມີຜົນກະທົບຕໍ່ເວລາດຳເນີນງານຂອງເຄື່ອງປັ່ນໄຟ Cummins ແລະ ໃຫ້ຂໍ້ມູນລະອຽດເພື່ອເພີ່ມປະສິດທິພາບການໃຊ້ນ້ຳມັນຂອງທ່ານ.

ອັດຕາການບໍລິໂภກເຊື້ອໄຟຟ້າແມ່ນແຕກຕ່າງກັນຢ່າງຫຼວງຫຼາຍໃນຮຸ່ນເຄື່ອງປັ່ນໄຟຟ້າ Cummins ຕ່າງໆ, ເງື່ອນໄຂການໂຫຼດ ແລະ ປັດໄຈດ້ານສິ່ງແວດລ້ອມ. ເຄື່ອງປັ່ນໄຟຟ້າທີ່ຖືກຂະຫນາດຢ່າງເຫມາະສົມ ແລະ ດຳເນີນງານໃນເງື່ອນໄຂທີ່ດີທີ່ສຸດສາມາດສະຫນອງພະລັງງານທີ່ເຊື່ອຖືໄດ້ເປັນໄລຍະຍາວ, ເຮັດໃຫ້ການເຂົ້າໃຈເຫດຜົນການດຳເນີນງານນີ້ເປັນສິ່ງຈຳເປັນສຳລັບການວາງແຜນສຸກເສີນ ແລະ ການດຳເນີນງານຢ່າງຕໍ່ເນື່ອງ.

ປັດໄຈຫຼັກທີ່ມີຜົນກະທົບຕໍ່ການບໍລິໂภກເຊື້ອໄຟຟ້າຂອງເຄື່ອງປັ່ນໄຟຟ້າ Cummins

ຂະຫນາດ ແລະ ອັນດັບພະລັງງານຂອງເຄື່ອງປັ່ນໄຟຟ້າ

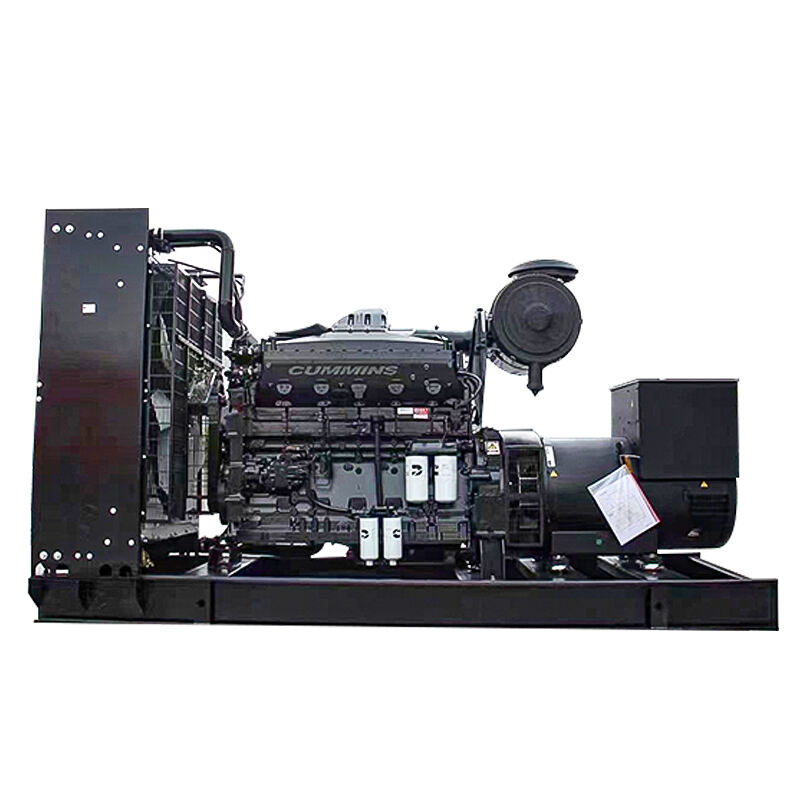

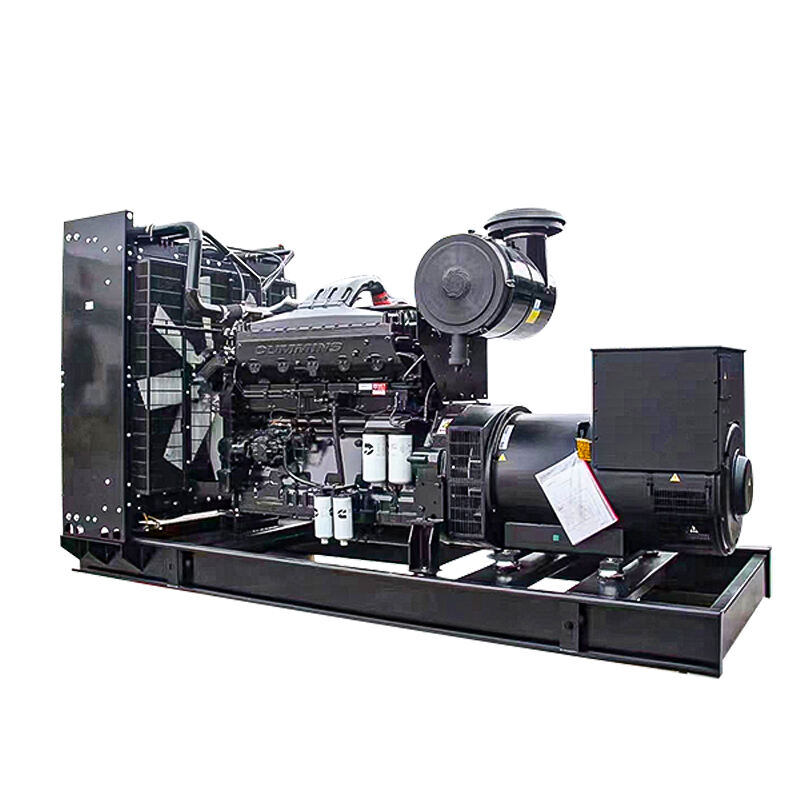

ຂະຫນາດ ແລະ ອັນດັບພະລັງງານຂອງ ເຊັດສະຖານປະລິດຄັນນິນ ມີບົດບາດພື້ນຖານໃນການບໍລິໂภກເຊື້ອໄຟຟ້າ. ເຄື່ອງປັ່ນໄຟຟ້າຂະຫນາດໃຫຍ່ທີ່ມີອັນດັບພະລັງງານສູງຈະບໍລິໂภກເຊື້ອໄຟຟ້າຫຼາຍຂຶ້ນເພື່ອຮັກສາຄວາມສາມາດໃນການຜະລິດພະລັງງານ. ຕົວຢ່າງ, ເຄື່ອງປັ່ນໄຟຟ້າ Cummins ຂະຫນາດ 20kW ສຳລັບທີ່ຢູ່ອາໄສຈະບໍລິໂภກເຊື້ອໄຟຟ້າໜ້ອຍກວ່າຢ່າງຫຼວງຫຼາຍເມື່ອທຽບກັບເຄື່ອງຂະຫນາດ 100kW ສຳລັບການຄ້າ.

ການເຂົ້າໃຈຄວາມຕ້ອງການພະລັງງານຂອງທ່ານຈະຊ່ວຍໃນການເລືອກເຄື່ອງປັ່ນໄຟຟ້າທີ່ເໝາະສົມ, ເຊິ່ງມີຜົນກະທົບໂດຍตรงຕໍ່ປະສິດທິພາບຂອງເຊື້ອໄຟ. ເຄື່ອງປັ່ນໄຟຟ້າທີ່ໃຫຍ່ເກີນໄປທີ່ດຳເນີນງານໃນສະພາບພຽງເລັກນ້ອຍຈະມີປະສິດທິພາບຕ່ຳ, ໃນຂະນະທີ່ເຄື່ອງທີ່ນ້ອຍເກີນໄປຈະເຮັດໃຫ້ເກີດຄວາມກົດດັນໃນການຕອບສະໜອງຄວາມຕ້ອງການ ແລະ ອາດຈະບັນທຸກເຊື້ອໄຟຫຼາຍກວ່າທີ່ຈຳເປັນ.

ເປີເຊັນຂອງພະລັງງານ ແລະ ອັດຕາການບັນທຸກ

ພະລັງງານໄຟຟ້າທີ່ຖືກວາງໄວ້ໃນເຄື່ອງປັ່ນໄຟຟ້າ Cummins ຂອງທ່ານມີຜົນກະທົບຢ່າງຫຼວງຫຼາຍຕໍ່ອັດຕາການບັນທຸກເຊື້ອໄຟ. ເຄື່ອງປັ່ນໄຟຟ້າສ່ວນຫຼາຍຈະບັນລຸປະສິດທິພາບສູງສຸດເມື່ອດຳເນີນງານຢູ່ 75-85% ຂອງຄວາມສາມາດທີ່ໄດ້ກຳນົດໄວ້. ໃນສະພາບພະລັງງານຕ່ຳ, ປະສິດທິພາບຂອງເຊື້ອໄຟຈະຫຼຸດລົງ, ໃນຂະນະທີ່ພະລັງງານທີ່ສູງເກີນໄປອາດຈະເຮັດໃຫ້ລະບົບເກີດຄວາມກົດດັນ ແລະ ເພີ່ມການບັນທຸກເຊື້ອໄຟ.

ເຄື່ອງປັ່ນໄຟຟ້າ Cummins ທີ່ມີຂະໜາດ 50kW ທຳມະດາທີ່ດຳເນີນງານຢູ່ 75% ຂອງພະລັງງານອາດຈະບັນທຸກປະມານ 4.1 ແກລອນຕໍ່ຊົ່ວໂມງ, ໃນຂະນະທີ່ເຄື່ອງດຽວກັນນັ້ນທີ່ດຳເນີນງານຢູ່ 25% ຂອງພະລັງງານອາດຈະໃຊ້ປະມານ 1.8 ແກລອນຕໍ່ຊົ່ວໂມງ. ຄວາມແຕກຕ່າງນີ້ສະແດງໃຫ້ເຫັນວ່າການຈັດການພະລັງງານມີຜົນກະທົບໂດຍກົງຕໍ່ການຄິດໄລ່ເວລາດຳເນີນງານ.

ການຄິດໄລ່ເວລາດຳເນີນງານ ແລະ ການຈັດການເຊື້ອໄຟ

ການນຳໃຊ້ສູດຄິດໄລ່ເວລາດຳເນີນງານພື້ນຖານ

ເພື່ອຄຳນວນເວລາໃຊ້ງານສຳລັບເຄື່ອງກຳເນີດໄຟຟ້າ Cummins ທີ່ມີນ້ຳມັນ 100 ແກລອນ, ໃຫ້ແບ່ງປະລິມານນ້ຳມັນດ້ວຍອັດຕາການບໍລິໂภກຕໍ່ຊົ່ວໂມງ. ເຖິງຢ່າງໃດກໍຕາມ, ການຄຳນວນພື້ນຖານນີ້ຈຳເປັນຕ້ອງຄຳນຶງເຖິງປັດໄຈຕ່າງໆໃນໂລກຈິງ ເຊັ່ນ: ການປ່ຽນແປງຂອງພະລັງງານ ແລະ ສະພາບແວດລ້ອມ. ລຸ້ນຫຼາຍຮຸ່ນຂອງ Cummins ມີລະບົບຕິດຕາມນ້ຳມັນທີ່ທັນສະໄໝ ຊຶ່ງສາມາດໃຫ້ການຄາດຄະເນເວລາໃຊ້ງານທີ່ຖືກຕ້ອງຫຼາຍຂຶ້ນ ໂດຍອີງໃສ່ສະພາບການເຮັດວຽກໃນປັດຈຸບັນ.

ຕົວຢ່າງ, ຖ້າເຄື່ອງກຳເນີດໄຟຟ້າຂອງທ່ານບໍລິໂພກ 2.5 ແກລອນຕໍ່ຊົ່ວໂມງ ໃນເງື່ອນໄຂການເຮັດວຽກປົກກະຕິ, ນ້ຳມັນ 100 ແກລອນກໍຈະສາມາດໃຫ້ເວລາໃຊ້ງານໄດ້ 40 ຊົ່ວໂມງ. ເຖິງຢ່າງໃດກໍຕາມ, ປັດໄຈຕ່າງໆໃນການນຳໃຊ້ຈິງມັກຈະເຮັດໃຫ້ເວລາໃຊ້ງານສູງສຸດຕາມທິດສະດີຫຼຸດລົງ.

ຜົນກະທົບຂອງສະພາບແວດລ້ອມຕໍ່ປະສິດທິພາບນ້ຳມັນ

ສະພາບແວດລ້ອມມີຜົນກະທົບຢ່າງຫຼວງຫຼາຍຕໍ່ການບໍລິໂພກນ້ຳມັນ ແລະ ເວລາໃຊ້ງານຂອງເຄື່ອງກຳເນີດໄຟຟ້າ Cummins. ອຸນຫະພູມແວດລ້ອມທີ່ສູງ, ຄວາມສູງ, ແລະ ຄວາມຊື້ນ ສາມາດມີຜົນກະທົບຕໍ່ປະສິດທິພາບຂອງເຄື່ອງຈັກ ແລະ ອັດຕາການບໍລິໂພກນ້ຳມັນ. ການບຳລຸງຮັກສາຢ່າງປົກກະຕິຈຶ່ງມີຄວາມສຳຄັນເປັນພິເສດໃນສະພາບແວດລ້ອມທີ່ທ້າທາຍ ເພື່ອຮັກສາປະສິດທິພາບການໃຊ້ນ້ຳມັນໃຫ້ດີທີ່ສຸດ.

ການດຳເນີນງານໃນສະພາບອາກາດທີ່ແຊບອາດຕ້ອງການເຊື້ອໄຟເພີ່ມເຕີມສຳລັບໄລຍະເວລາໃຫ້ຄວາມຮ້ອນ, ໃນຂະນະທີ່ສະຖານທີ່ທີ່ມີລະດັບຄວາມສູງອາດຈະມີປະສິດທິພາບຫຼຸດລົງຍ້ອນອາກາດທີ່ບາງລົງ. ປັດໃຈເຫຼົ່ານີ້ຄວນໄດ້ຮັບການພິຈາລະນາເມື່ອຄາດຄະເນເວລາໃນການດຳເນີນງານຈາກສາງເຊື້ອໄຟທີ່ກຳນົດ.

ການສູງສຸດຂອງເວລາໃນການດຳເນີນງານໂດຍຜ່ານການດຳເນີນງານຢ່າງມີປະສິດທິພາບ

ຍຸດທະສາດການຈັດການພະລັງງານ

ການນຳໃຊ້ຢ່າງມີປະສິດທິຜົນໃນການຈັດການພະລັງງານສາມາດຊ່ວຍຍືດເວລາໃນການດຳເນີນງານຂອງເຄື່ອງກຳເນີດໄຟຟ້າ Cummins ຂອງທ່ານໄດ້ຢ່າງຫຼວງຫຼາຍ. ນີ້ລວມເຖິງການຈັດລຽງລຳດັບຄວາມສຳຄັນໃນການໃຊ້ພະລັງງານ, ການນຳໃຊ້ນະໂຍບາຍການຫຼຸດຜ່ອນພະລັງງານໃນໄລຍະເວລາຂາດໄຟທີ່ຍາວນານ, ແລະ ຫຼີກລ່ຽງການໃຊ້ພະລັງງານທີ່ບໍ່ຈຳເປັນ. ເຄື່ອງກຳເນີດໄຟຟ້າ Cummins ລຸ້ນໃໝ່ມັກຈະມີຟັງຊັ່ນການຈັດການພະລັງງານຂັ້ນສູງທີ່ສາມາດໂປຣແກຣມເພື່ອເພີ່ມປະສິດທິພາບໃນການໃຊ້ເຊື້ອໄຟ.

ການຈັດຕັ້ງເວລາໃຊ້ພະລັງງານຢ່າງມີຍຸດທະສາດ ແລະ ການແຈກຢາຍຄວາມຕ້ອງການພະລັງງານຢ່າງສົມດຸນ ຊ່ວຍຮັກສາເງື່ອນໄຂການດຳເນີນງານໃຫ້ຢູ່ໃນລະດັບທີ່ດີທີ່ສຸດ. ວິທີການນີ້ບໍ່ພຽງແຕ່ຊ່ວຍຍືດເວລາໃນການດຳເນີນງານເທົ່ານັ້ນ ແຕ່ຍັງຊ່ວຍຮັກສາອາຍຸການໃຊ້ງານ ແລະ ຄວາມໜ້າເຊື່ອຖືຂອງເຄື່ອງກຳເນີດໄຟຟ້າ.

ຜົນກະທົບຂອງການບຳລຸງຮັກສາຕໍ່ປະສິດທິພາບໃນການໃຊ້ເຊື້ອໄຟ

ການບຳລຸງຮັກສາປົກກະຕິມີບົດບາດສຳຄັນໃນການຮັກສາປະສິດທິພາບການໃຊ້ນ້ຳມັນເຊື້ອໄຟ ແລະ ສູງສຸດຂອງເວລາໃນການໃຊ້ງານ. ກອງກອງນ້ຳມັນທີ່ສະອາດ, ລະດັບນ້ຳມັນທີ່ຖືກຕ້ອງ, ແລະ ກອງອາກາດທີ່ຖືກບຳລຸງຮັກສາຢ່າງດີ ທັງໝົດນີ້ຈະຊ່ວຍໃຫ້ການບັນທຶກການໃຊ້ນ້ຳມັນເຊື້ອໄຟໃນລະດັບທີ່ດີທີ່ສຸດ. Cummins ແນະນຳໃຫ້ມີການບຳລຸງຮັກສາຕາມແຜນການທີ່ກຳນົດໄວ້ຕາມເວລາໃຊ້ງານ ແລະ ເງື່ອນໄຂການເຮັດວຽກເພື່ອຮັບປະກັນປະສິດທິພາບສູງສຸດ.

ການບຳລຸງຮັກສາທີ່ຖືກເຊີດເຊີງອາດຈະນຳໄປສູ່ການເພີ່ມຂຶ້ນຂອງການໃຊ້ນ້ຳມັນເຊື້ອໄຟ, ເຊິ່ງອາດຈະຫຼຸດຜ່ອນເວລາໃຊ້ງານລົງ 10-15% ຫຼື ຫຼາຍກວ່ານັ້ນ. ການປະຕິບັດຕາມໄລຍະເວລາການບໍລິການທີ່ຜູ້ຜະລິດແນະນຳ ແລະ ການໃຊ້ອະໄຫຼ່ແທ້ຂອງ Cummins ຈະຊ່ວຍຮັກສາລະດັບປະສິດທິພາບທີ່ຖືກອອກແບບໄວ້.

ຄໍາ ຖາມ ທີ່ ມັກ ຖາມ

ຄວາມສູງມີຜົນກະທົບຕໍ່ການໃຊ້ນ້ຳມັນເຊື້ອໄຟຂອງເຄື່ອງປັ່ນໄຟ Cummins ຂອງຂ້ອຍແນວໃດ?

ໃນຄວາມສູງທີ່ສູງຂຶ້ນ, ເຄື່ອງປັ່ນໄຟໂດຍທົ່ວໄປຈະປະສົບກັບປະສິດທິພາບທີ່ຫຼຸດລົງຍ້ອນຄວາມໜາແໜ້ນຂອງອາກາດທີ່ຕ່ຳລົງ. ສຳລັບທຸກໆ 1,000 ຟຸດທີ່ຢູ່ເທິງລະດັບນ້ຳທະເລ, ທ່ານສາມາດຄາດຫວັງການຫຼຸດລົງປະມານ 3-4% ໃນຜົນຜະລິດພະລັງງານ ແລະ ການປັບປຸງທີ່ກ່ຽວຂ້ອງກັບອັດຕາການໃຊ້ນ້ຳມັນເຊື້ອໄຟ. ເຄື່ອງປັ່ນໄຟ Cummins ມີຄຸນສົມບັດການຊົດເຊີຍຄວາມສູງເພື່ອຊ່ວຍຮັກສາປະສິດທິພາບ.

ການທົດສອບໄຟຟ້າເປັນປະຈຳມີຜົນກະທົບແນວໃດຕໍ່ປະສິດທິພາບການໃຊ້ນ້ຳມັນ?

ການທົດສອບໄຟຟ້າເປັນປະຈຳຊ່ວຍຮັກສາສະພາບເຄື່ອງຈັກໃຫ້ຢູ່ໃນສະພາບທີ່ດີທີ່ສຸດ ແລະ ປະສິດທິພາບການໃຊ້ນ້ຳມັນໂດຍການປ້ອງກັນການຈັບຕົວຂອງຖ່ານກໍາມະຖັນ ແລະ ຮັບປະກັນວ່າລະບົບທັງໝົດດຳເນີນງານຢ່າງຖືກຕ້ອງ. ເຖິງແມ່ນວ່າການທົດສອບໄຟຟ້າຈະໃຊ້ນ້ຳມັນ, ແຕ່ຜົນປະໂຫຍດໃນດ້ານປະສິດທິພາບໃນໄລຍະຍາວມັກຈະຫຼາຍກວ່າປະລິມານນ້ຳມັນທີ່ໃຊ້ໃນຂະນະທີ່ກຳລັງທົດສອບ.

ຂ້ອຍຈະຕິດຕາມອັດຕາການໃຊ້ນ້ຳມັນຂອງເຄື່ອງກຳເນີດໄຟຟ້າໄດ້ແນວໃດຢ່າງຖືກຕ້ອງ?

ເຄື່ອງກຳເນີດໄຟຟ້າ Cummins ທີ່ຕິດຕັ້ງລະບົບຕິດຕາມທີ່ທັນສະໄໝສາມາດສະແດງຂໍ້ມູນການໃຊ້ນ້ຳມັນແບບເວລາຈິງ ແລະ ຄາດຄະເນເວລາດຳເນີນງານ. ສຳລັບຮຸ່ນເກົ່າ, ການບັນທຶກເວລາດຳເນີນງານ ແລະ ການໃຊ້ນ້ຳມັນດ້ວຍຕົນເອງຈະຊ່ວຍໃນການກຳນົດຮູບແບບການໃຊ້ນ້ຳມັນ. ລະບົບຕິດຕາມການໃຊ້ນ້ຳມັນມືອາຊີບກໍ່ສາມາດຕິດຕັ້ງໄດ້ເພື່ອຕິດຕາມຢ່າງແນ່ນອນ.