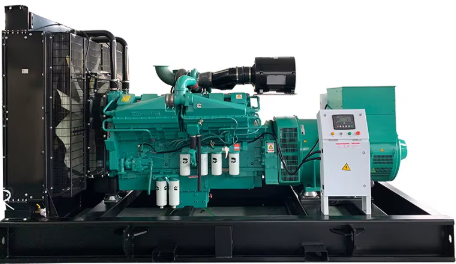

Introducción a la Generador de cummins Longevidad

Por qué el mantenimiento regular es importante para los generadores Cummins

Mantener bien los generadores de Cummins hace toda la diferencia para su rendimiento y cuánto tiempo realmente durarán. Cuando alguien hace controles regulares en estas máquinas, detecta pequeños problemas antes de que se conviertan en grandes dolores de cabeza. Y seamos realistas, nadie quiere lidiar con costosos fallos cuando los negocios están en auge. Los estudios muestran que las unidades correctamente mantenidas suelen durar aproximadamente un 30 por ciento más que las que se ignoran. El verdadero valor viene cuando las cosas siguen funcionando sin problemas sin sorpresas. Imagínese tratando de alimentar a toda una planta de fábrica y de repente todo se oscurece porque nadie se molestó en verificar los niveles de aceite el mes pasado. Este tipo de interrupción no planificada cuesta dinero rápidamente, especialmente en operaciones donde la electricidad simplemente no puede ser interrumpida ni siquiera por un minuto.

Entender el impacto de negligenciar el mantenimiento

Cuando el mantenimiento se ignora en los generadores Cummins, realmente se cobran un peaje en cómo funcionan y acorta su vida útil. Tomemos por ejemplo los cambios de aceite, omitirlos conduce a problemas de sobrecalentamiento y a un desgaste grave de los componentes del motor. La mayoría de las averías por mal mantenimiento ocurren porque los filtros de aire se obstruyen o los sistemas de combustible comienzan a funcionar mal, ambos factores que hacen que el generador trabaje más duro de lo necesario. Los estudios indican que no mantenerse al día con los controles de mantenimiento de rutina puede duplicar los gastos de operación con el tiempo, ya que las reparaciones se vuelven mucho más caras más tarde. Es por eso que seguir con los horarios de mantenimiento adecuados sigue siendo importante si alguien quiere que su generador funcione eficientemente durante años.

Aspectos Esenciales del Mantenimiento Programado

Revisar Diariamente: Niveles de Aceite, Fugas y Filtros de Aire

Comprobar su generador Cummins a diario lo mantiene funcionando sin problemas sin ninguna sorpresa en el camino. Lo primero, mira los niveles de aceite. El bajo aceite puede arruinar un motor con el tiempo, así que mantenerlo lleno hace toda la diferencia. No olvides revisar si hay fugas. Las gotas pequeñas pueden parecer inofensivas pero tienden a empeorar con el tiempo, causando mayores dolores de cabeza más adelante. Los filtros de aire también necesitan atención. Limpialas con regularidad y reemplazalas cuando sea necesario porque los filtros sucios dejan que el polvo y la suciedad entren a lugares donde no deberían estar. Esta cosa se acumula dentro del motor y eventualmente causa daños reales que cuestan dinero reparar.

Tareas Semanales: Inspecciones del Sistema de Combustible y Cuidado de la Batería

El mantenimiento regular del generador significa revisar semanalmente el sistema de combustible para detectar cualquier obstrucción o agua que entre, ya que estos problemas realmente afectan su funcionamiento. No olvides la batería tampoco. Un buen chequeo de la batería hace toda la diferencia cuando se trata de arrancar cosas, especialmente en clima frío. Limpia esos terminales y pruebalos de vez en cuando para mantener la batería más tiempo del esperado. La calidad del combustible también importa. El combustible malo va a gastar en los inyectores con el tiempo y hacer que los motores trabajen más duro de lo que necesitan, lo que nadie quiere. Pregunte a cualquiera que haya tratado con un generador que no se dispara al primer intento después de pasar meses sin usar.

Procedimientos Mensuales: Análisis del refrigerante y ajustes de tensión de las correas

El análisis del líquido refrigerante debe formar parte de las rutinas de mantenimiento mensuales regulares. Verificar el líquido de enfriamiento permite a los técnicos detectar cualquier descomposición química o contaminación desde el principio para que los generadores permanezcan dentro de las temperaturas de funcionamiento seguras. También se requiere ajustar la tensión de los cinturones cada mes porque los cinturones sueltos se desgastan más rápido y tienden a resbalar, lo que podría provocar serios problemas en el futuro. Mantener registros de todas estas inspecciones mensuales resulta ser bastante valioso en realidad. Los datos recopilados a lo largo del tiempo muestran patrones que los equipos de mantenimiento pueden observar para problemas recurrentes antes de que comiencen a afectar el funcionamiento del generador día a día.

Revisones Anuales: Evaluación del juego de válvulas y turboalimentador

La revisión anual ofrece una excelente oportunidad para examinar de cerca la salud real del generador, especialmente cuando se trata de las partes que más importan para el rendimiento. Conseguir el espacio libre de la válvula correcto hace toda la diferencia en la prevención de esa frustración de la caída de potencia que sucede cuando los motores no funcionan correctamente. Revisar los turbocompresores es otro elemento imprescindible durante estas inspecciones. Los mecánicos pueden detectar pequeñas grietas o patrones de desgaste que podrían indicar problemas mayores en el futuro si no se controlan. Para cualquiera que ejecute un generador Cummins, atenerse a este programa de mantenimiento anual no es sólo una buena práctica es prácticamente esencial para mantener las cosas funcionando sin problemas año tras año y evitar esas costosas averías que nadie quiere lidiar.

Técnicas Avanzadas de Preservación

Estrategias Óptimas de Lubricación con Aceites Sintéticos

Los aceites sintéticos de alta calidad hacen una gran diferencia cuando se trata de mejorar el rendimiento del motor y reducir el desgaste con el tiempo. Estos productos sintéticos resisten mucho mejor la degradación en condiciones difíciles en comparación con los aceites normales, lo que significa que protegen mucho mejor los motores en situaciones reales. Comprobar el espesor del aceite con regularidad es muy importante para mantener los generadores funcionando bien sin importar la temperatura exterior. Cuando la gente se queda con este simple hábito, sus motores tienden a funcionar mejor durante más tiempo, y el generador dura bastante más tiempo también.

Mantenimiento del Sistema de Refrigerante para el Control de Temperatura

Mantener el sistema de refrigerante en buena forma es muy importante para controlar el calor del generador durante el funcionamiento. La gente debe comprobar regularmente si hay alguna señal de fugas o esas molestas burbujas de aire que se forman en las líneas de refrigerante porque esto hace una gran diferencia en lo bien que todo funciona juntos. Cuando hay suficiente líquido de enfriamiento y es realmente limpio en lugar de como lodo, el motor funciona mejor y dura más que si se descuida. La mayoría de los técnicos le dirán a cualquiera que escuche que reservar tiempo para estos controles básicos como parte de las rutinas normales de mantenimiento detiene los problemas antes de que comiencen, especialmente porque el sobrecalentamiento puede destruir componentes caros en el futuro.

Protocolos de almacenamiento a largo plazo para prevenir la corrosión

Hacer que el almacenamiento sea correcto con el tiempo es muy importante para mantener los generadores en buena forma. Cosas como vaciar los viejos tanques de combustible y poner algún tipo de inhibidor de óxido realmente hacen una diferencia en su durabilidad. Cuando sea posible, almacenar unidades donde la temperatura se mantenga estable reduce toda esa humedad que hace que las piezas metálicas se corroe tan rápido. La mayoría de la gente olvida esta parte pero las inspecciones regulares mientras se sientan ociosos en realidad atrapan pequeños problemas antes de que se conviertan en grandes dolores de cabeza más tarde. Una rápida mirada a los niveles de aceite, comprobando si hay olores extraños que vengan del compartimento del motor, esas pequeñas cosas hacen mucho para asegurarse de que todo arranque sin problemas cuando alguien necesite energía de nuevo después de meses o incluso años de estar sentado sin usar.

Prácticas operativas óptimas para un rendimiento máximo

Gestión de carga: Evitando sobrecargas y subcargas

La gestión adecuada de la carga es esencial para mantener los generadores funcionando sin problemas a sus niveles de capacidad previstos. Cuando un generador se sobrecarga, tiende a sobrecalentarse lo que puede conducir a serios problemas en el camino y acortar su vida útil. Por otro lado, si el generador no está lo suficientemente cargado, puede que no queme el combustible completamente, lo que resulta en una acumulación de carbono dentro del motor y hace que todo el sistema trabaje más duro de lo necesario. La mayoría de los expertos de la industria sugieren que se apunte a una carga de alrededor del 70 a 80 por ciento como punto óptimo para obtener mejores resultados y una vida útil más larga del equipo. Mantener estos números generalmente mejora la eficiencia con la que el generador convierte el combustible en energía, mientras se reducen los gastos de reparación y se evitan esas pequeñas averías frustrantes que nadie quiere durante las operaciones críticas.

Consideraciones ambientales: Ventilación y control de humedad

El medio ambiente es muy importante para mantener los generadores funcionando confiablemente a lo largo del tiempo. Una buena circulación de aire alrededor de la unidad evita que las cosas se calienten demasiado porque deja que el calor escape correctamente. Sin suficiente aire fresco que circula, especialmente en espacios estrechos donde los generadores se encuentran a menudo, las temperaturas siguen subiendo hasta que algo se rompe. El control de humedad es otro gran problema también. Si el vapor de agua se acumula dentro de la carcasa del generador, se convierte en condensación que consume los componentes metálicos y eventualmente causa fallas. Es por eso que muchas instalaciones instalan deshumidificadores específicamente en las salas de generadores. Estos dispositivos reducen significativamente los niveles de humedad, protegiendo contra manchas de óxido y otros problemas de daño por agua que acortan considerablemente la vida útil del equipo.

Sistemas de Monitoreo: Aprovechando la Diagnóstico Remoto

Hoy en día, la mayoría de los generadores modernos vienen con tecnología de monitoreo sofisticada que rastrea los números de rendimiento a través de diagnóstico remoto a medida que ocurren. La gran ventaja es que se detectan problemas antes de que se vuelvan graves, lo que reduce los apagones inesperados y ahorra dinero en reparaciones. Cuando los técnicos observan todos estos datos que llegan de los sistemas de monitoreo, detectan patrones en cómo funciona el generador y planean el mantenimiento en torno a esas ideas en lugar de simplemente seguir un calendario. Incorporar el diagnóstico remoto en las rutinas de mantenimiento regular aumenta la confiabilidad del generador con el tiempo. Las instalaciones que han hecho este cambio informan menos averías y un mejor rendimiento general de sus equipos de generación de energía.

Conclusión: maximizar la vida útil de su generador Cummins

Lecciones clave para una fiabilidad constante

Obtener una buena fiabilidad y un rendimiento duradero de los generadores Cummins realmente depende de hacer un mantenimiento regular antes de que ocurran problemas. El diseño de un plan de mantenimiento sólido hace una gran diferencia en la duración de estas máquinas y en su rendimiento general. Cuando los operadores se adhieren a este tipo de programa de chequeos de rutina, todo dentro sigue funcionando correctamente lo que reduce esas molestas averías sorpresa que nadie quiere. Y no olvidemos también el personal de formación porque cuando la gente entiende qué necesita atención y por qué, tienden a detectar problemas antes. Este tipo de conocimiento práctico realmente ahorra dinero a largo plazo ya que las reparaciones menores se detectan temprano y evitan costosas reparaciones de emergencia más adelante.

Construir una Mentalidad Proactiva de Mantenimiento

Cuando los operadores desarrollan una actitud proactiva respecto al mantenimiento, tienden a trabajar de manera más inteligente en lugar de más duro, lo que aumenta la eficiencia y la productividad en todos los ámbitos. Las sesiones de formación y talleres regulares ayudan realmente al personal a sentirse cómodo con las técnicas de mantenimiento adecuadas. Muchas fábricas han descubierto que cuando ofrecen recompensas por mantener las máquinas en perfecto estado, los trabajadores empiezan a cuidar mejor las máquinas como si fueran suyas. Algunas empresas incluso asocian bonos a los registros de mantenimiento o crean competiciones amistosas entre equipos. ¿Qué resultado tuvo? Los generadores duran más y funcionan mejor durante toda su vida útil. Los operadores que entienden qué hace que sus equipos funcionen simplemente hacen que las cosas vayan mejor día a día.

Preguntas frecuentes

¿Con qué frecuencia debo realizar mantenimiento a mi generador Cummins?

El mantenimiento varía según el uso, pero se recomienda realizar verificaciones diarias de los niveles de aceite, inspecciones semanales del sistema de combustible, análisis mensuales del refrigerante y revisiones anuales para garantizar un rendimiento óptimo.

¿Cuáles son los riesgos de no realizar un mantenimiento regular?

Descuidar el mantenimiento puede llevar al desgaste del motor, filtros de aire obstruidos, sistemas de combustible comprometidos y una eficiencia reducida, lo que puede aumentar los costos operativos y disminuir la vida útil del generador.

¿Pueden los aceites sintéticos hacer una diferencia en el mantenimiento del generador?

Sí, los aceites sintéticos ofrecen una protección superior en condiciones extremas y ayudan a mantener un rendimiento óptimo del motor, prolongando así la vida útil del generador.

¿Por qué es importante el control ambiental para el almacenamiento del generador?

Controlar la humedad y asegurar una ventilación adecuada ayuda a prevenir la corrosión y el sobrecalentamiento, lo que puede comprometer la eficiencia y longevidad del generador.

Tabla de Contenido

- Introducción a la Generador de cummins Longevidad

- Por qué el mantenimiento regular es importante para los generadores Cummins

- Entender el impacto de negligenciar el mantenimiento

-

Aspectos Esenciales del Mantenimiento Programado

- Revisar Diariamente: Niveles de Aceite, Fugas y Filtros de Aire

- Tareas Semanales: Inspecciones del Sistema de Combustible y Cuidado de la Batería

- Procedimientos Mensuales: Análisis del refrigerante y ajustes de tensión de las correas

- Revisones Anuales: Evaluación del juego de válvulas y turboalimentador

- Técnicas Avanzadas de Preservación

- Prácticas operativas óptimas para un rendimiento máximo

- Conclusión: maximizar la vida útil de su generador Cummins

-

Preguntas frecuentes

- ¿Con qué frecuencia debo realizar mantenimiento a mi generador Cummins?

- ¿Cuáles son los riesgos de no realizar un mantenimiento regular?

- ¿Pueden los aceites sintéticos hacer una diferencia en el mantenimiento del generador?

- ¿Por qué es importante el control ambiental para el almacenamiento del generador?