Understanding the Revolution in Low-Noise Backup Power Solutions

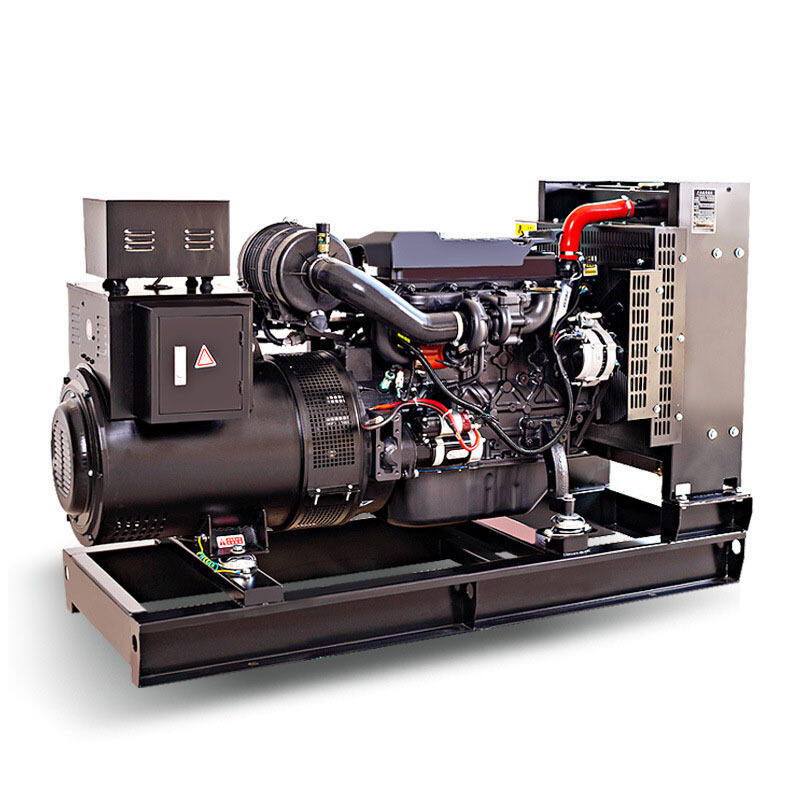

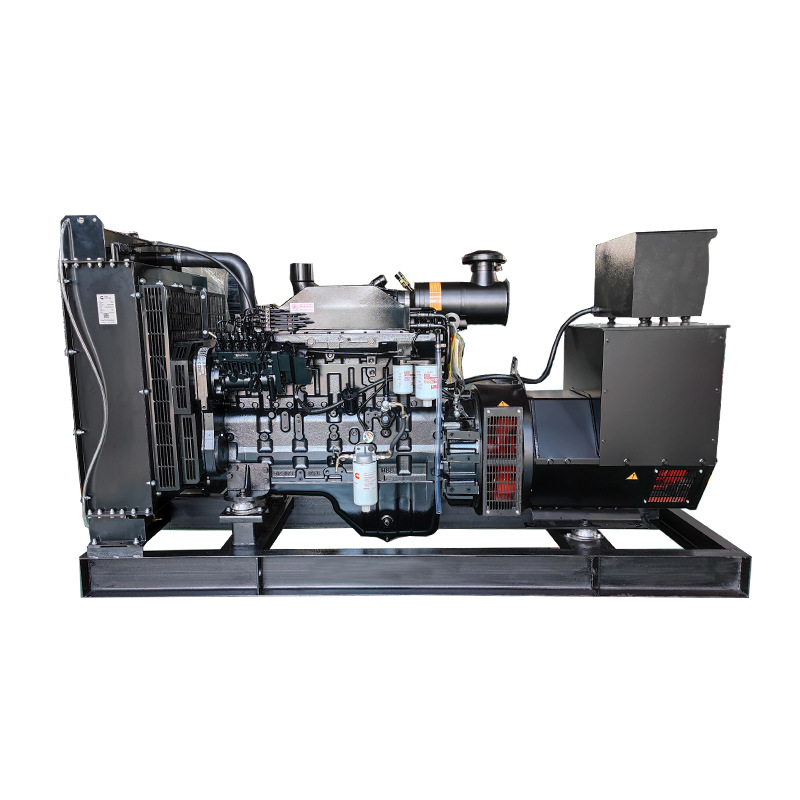

The evolution of power generation technology has reached a remarkable milestone with the latest quiet Cummins generator set innovations. Operating at just 65 decibels – comparable to normal conversation levels – these advanced power solutions are transforming how facilities maintain their critical operations while preserving environmental serenity. For context, traditional generators typically produce 85-95 dB, making these new models a significant leap forward in noise reduction technology.

In an era where uninterrupted power supply is non-negotiable, especially for healthcare facilities and residential areas, the importance of silent operation cannot be overstated. The quiet Cummins generator set represents a perfect confluence of robust performance and acoustic engineering, delivering reliable power without the characteristic noise pollution associated with conventional generators.

Advanced Engineering Behind Noise Reduction

Innovative Sound Attenuation Technology

At the heart of the quiet Cummins generator set lies a sophisticated sound attenuation system. The engineering team has implemented multiple layers of sound-dampening materials, strategically positioned to absorb and deflect sound waves. Advanced acoustic insulation, combined with precision-engineered enclosures, creates an effective barrier against noise transmission while maintaining optimal operating temperatures.

The enclosure design incorporates specialized air intake and exhaust systems that minimize sound escape while ensuring proper airflow. These systems utilize advanced baffle technology and sound-absorbing materials to trap and dissipate sound waves before they can propagate into the surrounding environment.

Vibration Isolation Systems

Mechanical vibration, a primary source of generator noise, is effectively controlled through an advanced isolation system. The quiet Cummins generator set employs sophisticated spring and rubber isolators that separate the engine-generator assembly from the mounting surface. This isolation system prevents vibration transfer to the foundation and surrounding structures, significantly reducing structural-borne noise.

Additionally, flexible connections between components eliminate metal-to-metal contact points, further reducing vibration transmission. The result is a remarkably smooth operation that contributes to the overall 65 dB noise level achievement.

Healthcare Facility Applications

Meeting Critical Care Environment Requirements

Hospitals and healthcare facilities present unique challenges for backup power systems. The quiet Cummins generator set excels in these environments by maintaining essential power supply without disrupting patient care or recovery. The 65 dB noise level ensures that patients can rest undisturbed, while medical equipment continues to function reliably during power transitions.

These generators are particularly valuable in areas near patient rooms, operating theaters, and diagnostic centers where noise sensitivity is paramount. The reduced sound output helps maintain the healing environment while providing the reliable backup power that healthcare facilities demand.

Compliance and Performance Standards

Healthcare facility generators must meet strict regulatory requirements and performance standards. The quiet Cummins generator set not only meets but exceeds these standards, incorporating features like rapid response time, voltage stability, and seamless power transition. The sound attenuation features do not compromise the system's ability to deliver consistent, clean power for sensitive medical equipment.

Regular maintenance and testing can be conducted during normal hospital operations without creating disruptive noise levels, ensuring continuous readiness without impacting patient care or staff operations.

Residential and Suburban Applications

Neighborhood-Friendly Power Solutions

Suburban environments demand power solutions that respect community noise ordinances and maintain neighborhood tranquility. The quiet Cummins generator set provides homeowners and residential facilities with reliable backup power while being an excellent neighbor. At 65 dB, these generators can operate during power outages without disturbing nearby residents or violating local noise regulations.

The aesthetic design of these generators also considers suburban integration, with sleek enclosures and compact footprints that blend seamlessly with residential landscapes. This combination of visual and acoustic consideration makes them ideal for installation near property lines or in densely populated areas.

Smart Integration Features

Modern suburban applications benefit from the intelligent control systems integrated into the quiet Cummins generator set. These features include programmable exercise schedules during appropriate hours, remote monitoring capabilities, and automatic adjustment of operating parameters to optimize performance and minimize noise output based on power demand.

The smart integration extends to compatibility with home automation systems, allowing homeowners to monitor generator status, receive maintenance alerts, and control operation through mobile devices or home control panels.

Maintenance and Long-term Performance

Preserving Noise Reduction Efficiency

Maintaining the 65 dB noise level over time requires proper attention to the generator's sound attenuation components. Regular inspections of acoustic materials, seals, and isolation systems ensure continued quiet operation. The quiet Cummins generator set includes easily accessible maintenance points, allowing technicians to perform routine services without compromising the noise reduction features.

Preventive maintenance schedules specifically address components that could impact noise levels, such as exhaust system integrity, enclosure seals, and vibration isolator condition. This proactive approach helps maintain optimal performance and noise characteristics throughout the generator's service life.

Performance Monitoring and Optimization

Advanced monitoring systems track both power output and noise levels, allowing for early detection of any deviations from optimal performance. The quiet Cummins generator set includes sophisticated diagnostic tools that help maintenance teams identify and address potential issues before they affect noise levels or operational efficiency.

Regular performance testing under various load conditions ensures that the generator maintains its noise specifications while delivering reliable power. This comprehensive approach to maintenance and monitoring protects the initial investment and ensures long-term satisfaction with both performance and noise control.

Frequently Asked Questions

How does weather affect the noise level of these generators?

The quiet Cummins generator set maintains consistent noise levels across various weather conditions. The enclosure design accounts for rain, wind, and temperature variations, ensuring that the 65 dB rating remains stable. However, extreme weather conditions may require additional maintenance checks to ensure all sound attenuation components continue functioning optimally.

Can the generator maintain the 65 dB level under full load?

Yes, these generators are engineered to maintain their 65 dB noise level even under full load conditions. The sound attenuation system is designed to handle maximum output scenarios while continuing to provide effective noise control. Regular load bank testing confirms this performance capability.

What is the recommended maintenance schedule for noise control components?

The sound attenuation system should be inspected quarterly, with detailed examination of acoustic materials and seals. Vibration isolators require annual assessment, while the complete acoustic system should undergo professional evaluation every two years. Following this maintenance schedule helps ensure continued quiet operation.