Understanding the Power and Performance of Modern Cummins Generator Sets

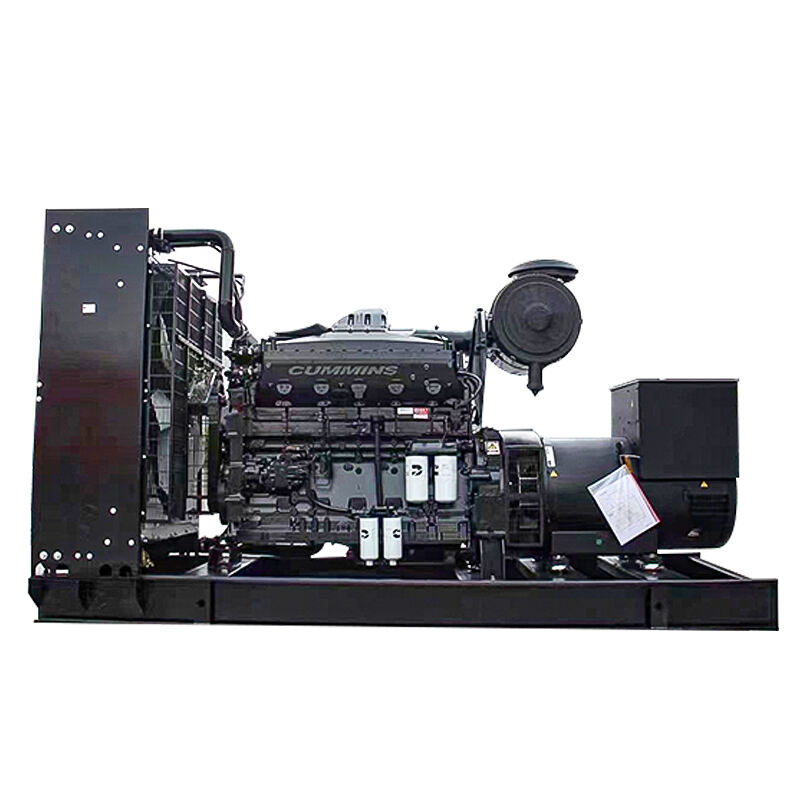

The industrial power generation landscape continues to evolve, and at the forefront of this evolution stands the Cummins generator set lineup for 2025. These power solutions have become the backbone of reliable energy supply across diverse applications, from small commercial establishments to large industrial complexes. As we delve into the comprehensive comparison between 50 kW and 500 kW models, we'll explore how these robust power solutions deliver unmatched performance, efficiency, and reliability.

The latest Cummins generator set innovations represent a significant leap forward in power generation technology. With enhanced digital capabilities, improved fuel efficiency, and advanced emission control systems, these units are designed to meet the growing demands of modern power applications while adhering to stringent environmental regulations.

Technical Specifications and Performance Metrics

50 kW Cummins Generator Set Features

The 50 kW Cummins generator set is engineered for optimal performance in light to medium-duty applications. It features a sophisticated electronic governor system that maintains steady frequency output under varying load conditions. The unit comes equipped with a robust alternator designed for maximum efficiency and minimal voltage distortion, making it ideal for sensitive electronic equipment.

Key specifications include a compact footprint measuring approximately 2.5 x 1.2 x 1.8 meters, making it suitable for installations with limited space. The engine operates at 1800 RPM for 60 Hz applications, delivering consistent power output while maintaining fuel efficiency. Advanced cooling systems ensure reliable operation in ambient temperatures up to 50°C.

500 kW Cummins Generator Set Capabilities

The 500 kW model represents the higher end of industrial power solutions, featuring advanced technologies for mission-critical applications. This Cummins generator set incorporates a heavy-duty engine block with enhanced durability features, including strengthened pistons and bearings for extended service life under continuous operation.

The unit boasts impressive specifications, including a sophisticated digital control system that enables real-time monitoring and remote management capabilities. With a larger footprint of approximately 4.5 x 2.0 x 2.5 meters, this powerhouse delivers exceptional performance with quick load response and superior motor-starting capability.

Cost Analysis and Investment Considerations

Initial Purchase and Installation Expenses

The investment landscape for Cummins generator sets varies significantly between the 50 kW and 500 kW models. The 50 kW unit typically requires an initial investment ranging from $25,000 to $35,000, while the 500 kW system commands a premium price point between $125,000 and $175,000. These base prices reflect the standard configuration, with additional costs for customization and advanced features.

Installation costs must also be carefully considered, as they can add 20-30% to the total investment. This includes site preparation, electrical infrastructure, fuel storage systems, and professional installation services. The 500 kW unit generally requires more extensive site preparation and specialized installation procedures, potentially increasing the total project cost by 35-45%.

Operational Costs and Long-term Value

When evaluating the total cost of ownership, fuel consumption becomes a critical factor. The 50 kW Cummins generator set typically consumes 3.5 to 4.5 gallons per hour under full load, while the 500 kW model uses approximately 35 to 40 gallons per hour at full capacity. Regular maintenance intervals, parts replacement, and service requirements must be factored into the long-term operational budget.

The return on investment timeline varies based on usage patterns and application requirements. For mission-critical applications, the higher initial cost of the 500 kW unit is often justified by its superior reliability and reduced downtime risk. The 50 kW model offers excellent value for intermittent use scenarios and smaller operations where continuous high-power output isn't necessary.

Application Scenarios and Industry Solutions

Optimal Uses for 50 kW Systems

The 50 kW Cummins generator set excels in various light commercial and institutional applications. Small to medium-sized retail establishments, medical clinics, and office buildings find this power rating ideal for maintaining essential operations during utility power interruptions. These units provide sufficient capacity to power critical systems, including emergency lighting, security systems, and basic climate control.

Educational facilities and small data centers also benefit from the reliability and efficiency of the 50 kW model. The unit's quick-start capability and stable power output ensure minimal disruption to operations during power transitions. Agricultural applications, particularly in modern farming operations, utilize these generators for irrigation systems and essential equipment power backup.

500 kW System Applications

The 500 kW Cummins generator set is designed for large-scale industrial and commercial applications where power demands are substantial and continuous operation may be required. Manufacturing facilities, large healthcare institutions, and data centers rely on these robust units for primary or backup power generation. The advanced load management capabilities ensure stable power delivery even under rapidly changing demand conditions.

Large retail complexes, hotels, and entertainment venues often deploy 500 kW units as part of their critical power infrastructure. These generators provide the capacity to maintain full operational capability during extended utility outages, protecting revenue streams and ensuring guest comfort and safety. Industrial processing plants utilize these units for peak shaving applications, helping to manage energy costs during high-demand periods.

Maintenance Requirements and Service Protocols

Preventive Maintenance Schedules

Regular maintenance is crucial for maintaining optimal performance and longevity of any Cummins generator set. The 50 kW model requires basic service intervals every 250-300 operating hours, including oil changes, filter replacements, and general inspections. Major service intervals occur at 1000-hour intervals, involving more comprehensive component checks and potential replacements.

The 500 kW unit demands more rigorous maintenance protocols, with basic service intervals every 200-250 operating hours due to its higher output and more complex systems. Comprehensive maintenance schedules include regular testing of load bank capacity, fuel system cleaning, and detailed analysis of operating parameters through the digital control system.

Frequently Asked Questions

What factors should influence my choice between a 50 kW and 500 kW Cummins generator set?

The selection should be based on your power requirements, application type, budget constraints, and growth projections. Consider factors such as peak load demands, running time requirements, and available installation space. The 50 kW unit suits smaller operations with intermittent backup needs, while the 500 kW system is ideal for large-scale continuous operations.

How do fuel efficiency and consumption compare between these models?

The 50 kW generator typically consumes 3.5-4.5 gallons per hour at full load, while the 500 kW unit uses approximately 35-40 gallons per hour. However, efficiency ratings are comparable when considered relative to power output. Both models incorporate advanced fuel management systems to optimize consumption based on load demands.

What are the typical warranty terms for Cummins generator sets?

Standard warranty coverage includes two years or 2,000 operating hours for both models, with extended warranty options available. Coverage encompasses manufacturer defects, major components, and control systems. Premium warranty packages can extend protection up to five years or 5,000 operating hours, depending on the application and usage patterns.