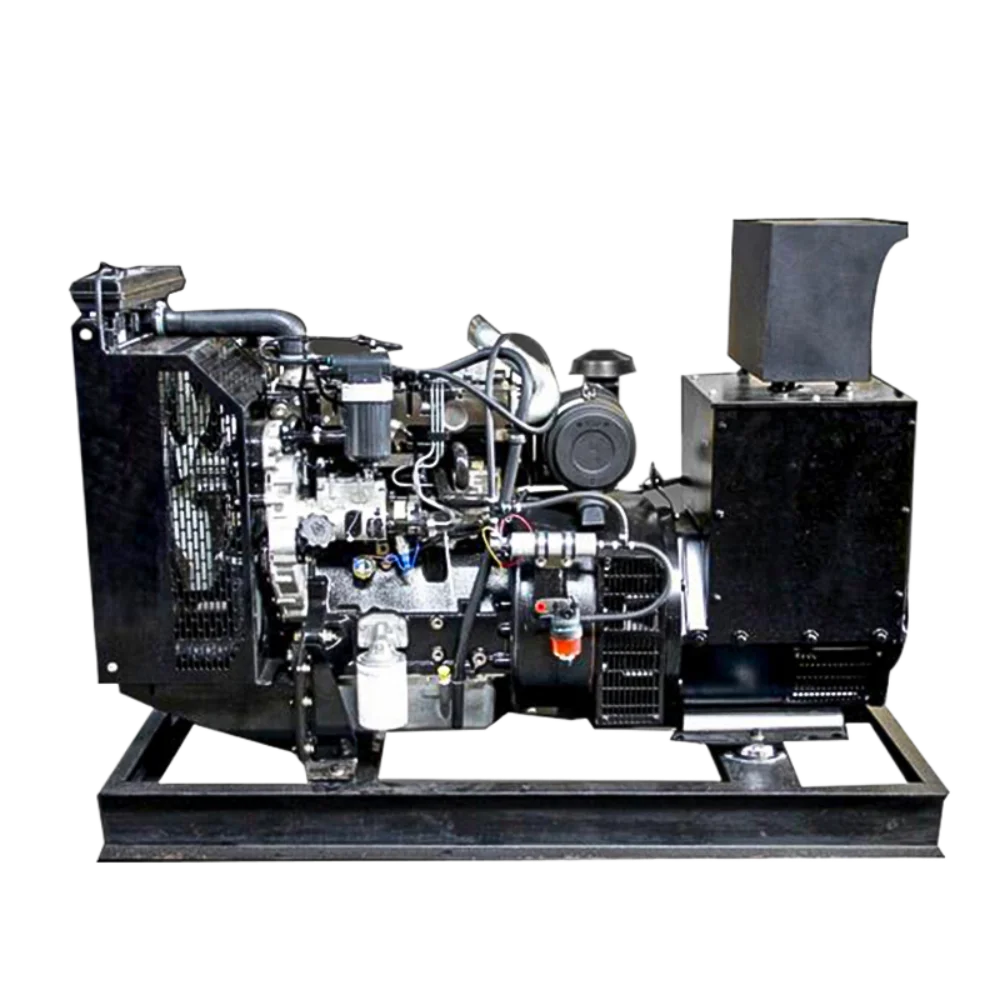

Монтирането на генераторна установка Perkins изисква внимателно планиране, правилна подготовка и спазване на протоколите за безопасност, за да се осигури оптимална производителност и дълготраен срок на служба. Независимо дали инсталирате резервно захранване за промишлени обекти, търговски сгради или жилищни приложения, разбирането на процеса на монтаж е от съществено значение за успешната експлоатация. Правилно монтирана генераторна установка Perkins осигурява надеждно производство на електроенергия по време на прекъсвания и може да се използва като основен източник на енергия в отдалечени райони, където няма достъп до мрежово електричество.

Планиране преди инсталиране и оценка на обекта

Избор на местоположение и околната среда

Изборът на оптимално местоположение за инсталиране на Вашия перкинсов генератор започва с оценка на околните фактори, които директно влияят на производителността и достъпа до поддръжката. Мястото за инсталиране трябва да осигурява достатъчно свободно пространство от всички страни, като обикновено се изискват минимални разстояния от три фута за рутинен достъп при поддръжка и подходяща вентилация. Вземете предвид преобладаващите посоки на вятъра, за да се гарантира, че изгорелите газове се разпръскват далеч от вентилационните отвори на сгради и населени зони.

Състоянието на почвата играе ключова роля за поемане на теглото и вибрационните натоварвания, възникващи по време на работа. Основата трябва да бъде равна, стабилна и способна да понесе експлоатационното тегло на генератора, както и динамичните натоварвания. От значение са и съображенията за дренаж, за да се предотврати натрупването на вода около уреда, което може да доведе до корозия и електрически опасности при влажно време.

Достъпът за доставка на гориво, персонал за поддръжка и възможен ремонт трябва да повлияе на решението ви за местоположението. Може да се наложи достъп за превозни средства за спешна помощ до генераторната установка на Perkins, като е необходимо достатъчно пространство за камиони и вдигателни устройства. Освен това вземете предвид разпространението на шума към съседни имоти и местните изисквания за зониране, които могат да ограничават поставянето или работните часове на генератора.

Анализ на електрическата натовареност и изисквания за размер

Провеждането на задълбочен анализ на електрическата натовареност осигурява, че генераторната установка на Perkins ще отговаря на настоящите и бъдещите нужди за енергия, без прекомерно увеличение или недостатъчен размер на инсталацията. Започнете с инвентаризация на всички критични натоварвания, които трябва да работят по време на прекъсвания на тока, включително системи за осветление, климатични уреди, хладилни агрегати, компютърни системи и основно производствено оборудване.

Изчислете както пусковите, така и работните натоварвания за всяко свързано устройство, тъй като оборудването с двигател често изисква значително по-висока мощност при стартиране в сравнение с постоянното работно състояние. Резерви за безопасност от 25–30% над изчислените натоварвания осигуряват резерв за бъдещо разширяване и гарантират генераторът да работи в оптимални граници на ефективност, а не непрекъснато при максимална мощност.

Напрежението и честотата трябва да отговарят на местните електрически стандарти и спецификациите на свързаното оборудване. Повечето модели перкинсови генераторни установки предлагат конфигурируеми изходни напрежения, но потвърждаването на съвместимостта преди монтажа предотвратява скъпи модификации или повреди по оборудването по време на пускане в експлоатация.

Подготовка на основата и механичен монтаж

Проектиране и строителство на бетонна основа

Правилно проектирана бетонна основа осигурява стабилна опора за вашия перкинсов генераторен агрегат, като в същото време минимизира предаването на вибрации към заобикалящите конструкции. Размерите на основата трябва да надхвърлят базата на генератора поне с шест инча от всички страни, като дебелината се определя от почвените условия и тегловните спецификации на генератора, посочени в монтажното ръководство на производителя.

Разположението на армировъчна стомана в бетонната основа подсилва конструктивната цялостност и предотвратява пукане при динамични натоварвания. Муфтите или шаблоните за анкерни болтове осигуряват точно позициониране на монтажните елементи, като изключват корекции на терен, които биха могли да нарушили подравняването или да създадат концентрации на напрежение в рамата на генератора.

Времето за втвърдяване на бетонните основи обикновено изисква 28 дни, за да се постигне пълна якост преди монтажа на генератора, макар че конкретните изисквания да могат да варират в зависимост от типа цимент и околните условия. Правилните методи за втвърдяване, включително запазване на влажността и контрол на температурата, осигуряват оптимална якост и дълготрайност на бетона за поддържане на Вашия перкинсов генератор през целия му експлоатационен живот.

Позициониране и процедури за монтиране на генератора

Поставянето на перкинсовия генератор върху подготвената основа изисква внимателно внимание към подравняването, нивелирането и фиксирането, за да се предотвратят работни проблеми и преждевременно износване. Използвайте подходящо повдигащо оборудване с номинална товароподемност според теглото на генератора, като следвате точките за вдигане, посочени от производителя, за избягване на повреди на кабината или вътрешните компоненти по време на монтажа.

Нивелирането на генератора в рамките на допуснатите от производителя отклонения, обикновено до 0,125 инча за дължината на основата, осигурява правилното разпределение на смазването и предотвратява прекомерни вибрации по време на работа. Прецизни нивелиращи инструменти и материали за подлагане помагат да се постигнат изискваните допуски, като се осигури стабилен контакт между основата на генератора и повърхността на фундамента.

Затеглянето на анкерните болтове следва специфични указания за момент на завъртане, посочени в документацията за монтаж, за да се гарантира сигурно закрепване без претоварване на рамата на генератора или фундамента. Могат да бъдат монтирани виброзащитни подложки между основата на генератора и фундамента, за да се намали предаването на шум и да се защити както оборудването, така и заобикалящите конструкции от експлоатационни вибрации.

Монтаж и конфигуриране на горивната система

Размери и изисквания за разположение на горивния резервоар

Конструкцията на горивната система за вашия генераторен агрегат на Perkins трябва да осигурява баланс между експлоатационните изисквания, изискванията за безопасност и достъпността при поддръжката, като същевременно осигурява достатъчен обем на горивото за очакваното време на работа. При изчисляването на размера на резервоара се вземат предвид скоростите на разход на гориво при различни нива на натоварване, желаните периоди на автономност и местните правила за пожарна безопасност, които могат да ограничават максималните количества съхранявано гориво в близост до сгради или имотни граници.

Подземните горивни резервоари спестяват пространство и осигуряват по-голяма сигурност, но изискват специализирани процедури за монтаж, включително системи за откриване на течове, защита от корозия и съответствие с екологичните разпоредби. Резервоарите, разположени над земята, позволяват по-лесен достъп за инспекции и поддръжка, но трябва да включват вторични системи за съдържане и мерки за противопожарна защита, както е задължително според местните власти.

Запазването на качеството на горивото е от решаващо значение за приложения с резервни генератори, при които горивото може да остане в складовите резервоари в продължение на дълги периоди. Конструкцията на резервоара трябва да включва решения за системи за кондициониране на горивото, отделяне на вода и пробни точки за наблюдение на качеството на горивото и предотвратяване на замърсяване, което би могло да повлияе генераторен комплект Perkins производителността по време на критични периоди на работа.

Маршрутизиране на горивните линии и процедури за свързване

Монтажът на горивни линии между складовия резервоар и генераторния агрегат на Perkins изисква внимателно маршрутизиране, за да се минимизират загубите на налягане, да се предотврати задържането на въздух и да се осигури лесен достъп за бъдещи операции по поддръжка. Основните горивни линии трябва да следват възможно най-директния път, като се избягват зони, където може да възникне механично повреда от движението на превозни средства или строителни дейности.

Линиите за връщане на гориво, които връщат загрято гориво обратно към резервоара, трябва да бъдат правилно подбрани по размер и прокарани така, че да се предотврати образуването на пари и да се осигури достатъчно охлаждане преди рециркулацията на горивото. Опорите и закрепването на горивните линии предотвратяват натоварване върху връзките с генератора, като същевременно компенсират топлинното разширение и нормалните вибрации по време на работа.

Монтажът на вентили за спиране на подаването на гориво, филтри и мониторингово оборудване следва спецификациите на производителя и изискванията на местните правила за възможност за аварийно спиране и защита на системата. Проверката на налягането в завършените горивни линии потвърждава цялостността на системата и идентифицира потенциални места на течове, преди пускане в експлоатация на перкинсовия генераторен агрегат.

Електрически връзки и интеграция на системата за управление

Разпределение на енергията и монтаж на превключвателен ключ

Електрическата интеграция на Вашия перкинсов генератор със съществуващите енергийни системи на обекта изисква внимателна координация между характеристиките на изхода на генератора и изискванията за разпределение на натоварването. Изборът на превключвател зависи от това дали се изисква ръчно или автоматично управление, като автоматичните превключватели осигуряват безпроблемни преходи на захранването по време на прекъсвания в доставката на електроенергия.

Основните електрически връзки от генератора до превключвателя трябва да бъдат подбрани според максималния изходящ ток на генератора и монтирани с използване на подходящи видове проводници за работната среда. Правилните заземителни връзки гарантират безопасността на персонала и защита на оборудването, като същевременно отговарят на изискванията на електрическия кодекс за инсталиране на генератори.

Модификации в разпределителните табла може да са необходими, за да се осигури разпределение на генераторната мощност, особено когато се изисква селективно захранване на критични вериги по време на аварийна работа. Приоритизирането на веригите позволява на задължителните натоварвания да работят непрекъснато, докато некритичните могат да бъдат изключени, за да съответстват на ограниченията на капацитета на генератора.

Конфигурация на командното табло и настройка на комуникацията

Съвременните командни табла на перкинсови генераторни агрегати предлагат сложни възможности за наблюдение и комуникация, които подобряват експлоатационната надеждност и позволяват дистанционен контрол на системата. Първоначалната конфигурация включва задаване на експлоатационни параметри като стойности за напрежение и честота, прагове за аларми и автоматични последователности за стартиране/спиране въз основа на условията на мрежовото захранване.

Настройката на комуникационния интерфейс осигурява интеграция със системи за управление на сгради или услуги за дистанционен мониторинг за предоставяне на актуална информация за състоянието и известяване при аларми. Мрежовите връзки позволяват автоматизирано изпращане на експлоатационни данни, графици за поддръжка и показатели за производителността на системата до персонала по управление на обекта.

Програмирането на проверъчни цикли и напомняния за поддръжка гарантира редовната работа на генераторната установка Perkins, за да се осигури готовност и смазване на компонентите. Автоматичните тестови последователности проверяват функционалността на системата без необходимост от ръчно вмешателство и документират данни за представянето с цел планиране на поддръжката.

Процедури за пускане в експлоатация и първоначално тестване

Стартиране на системата и проверка на производителността

Началните процедури за стартиране на новоинсталираната перкинсова генераторна установка следват систематичен подход за проверка дали всички системи функционират правилно, преди да бъде пусната в експлоатация. Проверките преди стартиране потвърждават нивата на течности, електрическите връзки, цялостността на горивната система и настройките на управлението съответстват ли на спецификациите за инсталиране и експлоатационните изисквания.

Първото стартиране на двигателя трябва да се извърши при минимално електрическо натоварване, за да се наблюдават характеристиките на работата на двигателя, включително налягането на маслото, циркулацията на охлаждащата течност и функционирането на изпускателната система. Постепенното увеличаване на натоварването по време на първоначалното тестване потвърждава регулирането на напрежението на генератора и стабилността на честотата при различни натоварвания.

Тестването на производителността включва измерване на изходното напрежение, стабилността на честотата и способността за поемане на натоварване, за да се потвърди, че генераторната установка перкинс отговаря на зададените критерии за производителност. Документирането на резултатите от тестовете осигурява базови данни за бъдещи сравнения на производителността и валидиране на гаранцията.

Проверка на системите за безопасност и обучение

Тестването на системите за безопасност потвърждава правилното функциониране на аварийни спирачи, алармени системи и защитни блокировки, които осигуряват защита на персонала и оборудването при нормални и аварийни работни условия. Процедурите за тестване трябва да симулират различни неизправности, за да се потвърди адекватният отговор на системата и активирането на сигналните предупреждения.

Сесиите за обучение запознават персонала на обекта с правилните процедури за стартиране и спиране, изискванията за рутинно поддържане и протоколите за аварийно реагиране. Документацията за обучението трябва да се съхранява, за да се демонстрира спазване на разпоредбите за безопасност и да се гарантират последователни експлоатационни практики.

Окончателното приемане на системата включва проверка дали цялата инсталационна работа отговаря на приложимите правила и стандарти, като същевременно предоставя на клиента пълен комплект документация, включваща гаранции, графици за поддръжка и информация за контакти в случай на аварийни ситуации за непрекъсната подкрепа.

Планиране на поддръжката и дългосрочна експлоатация

Разработване на графици за превантивно поддръжане

Създаването на изчерпателен график за поддръжка на Вашия генераторен агрегат перкинс осигурява надеждна работа и удължава живота на оборудването, като в същото време намалява неочакваните повреди по време на критични периоди на експлоатация. Интервалите за поддръжка зависят от работните часове, околните условия и качеството на горивото, като по-честа сервизна поддръжка е необходима за агрегати, работещи в прашни или екстремни температурни среди.

Редовните поддръжни дейности включват смяна на маслото и филтъра за масло, проверка и обслужване на системата за охлаждане, почистване на горивната система и смяна на филтъра, както и тестване на електрическата система, за да се осигури правилното функциониране на всички защитни устройства. Поддържането на батерията гарантира надеждно стартиране при аварийни ситуации, когато генераторът трябва бързо да реагира на прекъсвания в електрозахранването.

Документирането на всички дейности по поддръжка осигурява ценни данни за оптимизиране на интервалите за обслужване и идентифициране на тенденции, които могат да показват възникващи проблеми, преди те да доведат до експлоатационни повреди. Записите за поддръжка също подкрепят претенциите по гаранцията и доказват спазването на изискванията на производителя за продължаване на гаранционното покритие.

Мониторинг и стратегии за оптимизация на производителността

Непрекъснатото следене на работата на вашия генераторен агрегат Perkins идентифицира възможности за оптимизация, като едновременно открива постепенното влошаване на параметрите, което може да компрометира надеждността или ефективността. Редовното събиране на данни включва скоростта на горивните разходи, тенденциите в консумацията на масло, моделите на температурата на охлаждащата течност и измервания на качеството на електрическия изход.

Графиците за тестване под товар трябва да включват периодично пълно товарно тестване, за да се потвърди, че генераторът запазва способността си за номинален изход и да се идентифицира всяко влошаване на производителността, което изисква внимание. Тестването при реални натоварявания осигурява по-точна оценка в сравнение само с тестване без товар и помага за поддържане на двигателя и компонентите му в правилно работно състояние.

Мониторингът на качеството на горивото предотвратява проблеми, свързани със замърсяване, които биха могли да повлияят на производителността на двигателя или да причинят прекъсвания в работата по време на критични периоди. Редовното вземане и анализиране на проби от гориво идентифицира замърсяване с вода, разрастване на бактерии или химическа деградация, които изискват коригиращи действия за осигуряване на надеждна работа на перкинсов генераторен агрегат.

ЧЗВ

Какви изисквания за основата са необходими за инсталиране на перкинсов генераторен агрегат

Изискванията за основата на перкинсов генераторен агрегат зависят от размера на уреда и местните почвени условия, но обикновено изискват подложка от армиран бетон, разширена поне с 6 инча извън основата на генератора от всички страни. Основата трябва да бъде нивелирана в рамките на 0,125 инча и да е способна да поддържа експлоатационното тегло на генератора плюс динамичните натоварвания. Правилното дренажно оформяне около основата предотвратява натрупване на вода, което може да причини корозия или електрически рискове.

Колко свободно пространство е необходимо около генератора по време на инсталирането

Минималните изисквания за разстояния при инсталиране на генераторни установки Perkins обикновено включват 3 фута от страната за сервизно обслужване, за да се осигури достъп за поддръжка, 2 фута от останалите страни за вентилация и достатъчно свободно пространство над генератора за вдигане с подемно оборудване по време на сервизни дейности. Може да се изисква допълнително пространство за изпускателни тръбопроводи, свързвания за гориво и електрически кабели. Местните нормативи могат да изискват по-големи разстояния поради съображения за противопожарна безопасност или ниво на шум.

Какви електрически връзки са необходими за правилното инсталиране на генератор

Електрическите връзки за генераторна установка Perkins включват основни захранващи кабели с размер, подходящ за максимален изходящ ток, управляващи кабели към превключвателния ключ, заземяващи проводници за безопасност и комуникационни кабели за дистанционно наблюдение, ако е необходимо. Всички връзки трябва да отговарят на местните електрически нормативи и спецификациите на производителя. Правилното заземяване е задължително за безопасността на персонала и защита на оборудването.

Колко време обикновено отнема процесът по инсталиране на генераторна установка Perkins

Пълната инсталация на генераторна установка на Perkins обикновено изисква 3–7 дни, в зависимост от условията на обекта, изискванията за подготовката на основата и сложността на системата. Ако е необходим нов бетон, това добавя 28 дни към график-план за втвърдяване на основата. Метеорологичните условия, процесите за одобрение на разрешителни и координирането с енергийни доставчици за електрическите връзки могат да удължат общата продължителност на проекта. Правилното планиране и координиране минимизират времето за инсталиране, като осигуряват качествено изпълнение на работата.

Съдържание

- Планиране преди инсталиране и оценка на обекта

- Подготовка на основата и механичен монтаж

- Монтаж и конфигуриране на горивната система

- Електрически връзки и интеграция на системата за управление

- Процедури за пускане в експлоатация и първоначално тестване

- Планиране на поддръжката и дългосрочна експлоатация

-

ЧЗВ

- Какви изисквания за основата са необходими за инсталиране на перкинсов генераторен агрегат

- Колко свободно пространство е необходимо около генератора по време на инсталирането

- Какви електрически връзки са необходими за правилното инсталиране на генератор

- Колко време обикновено отнема процесът по инсталиране на генераторна установка Perkins