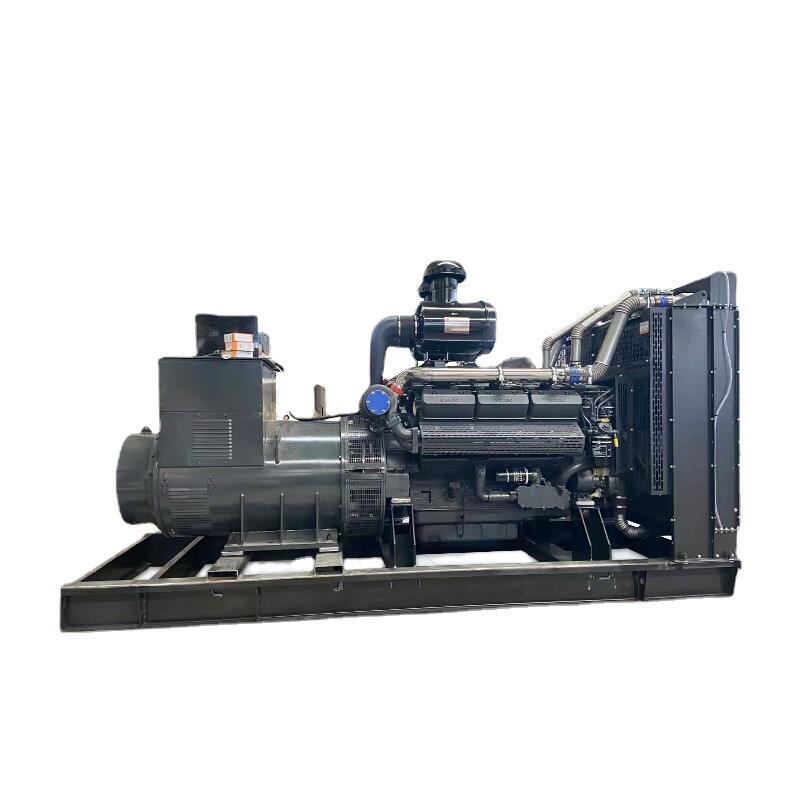

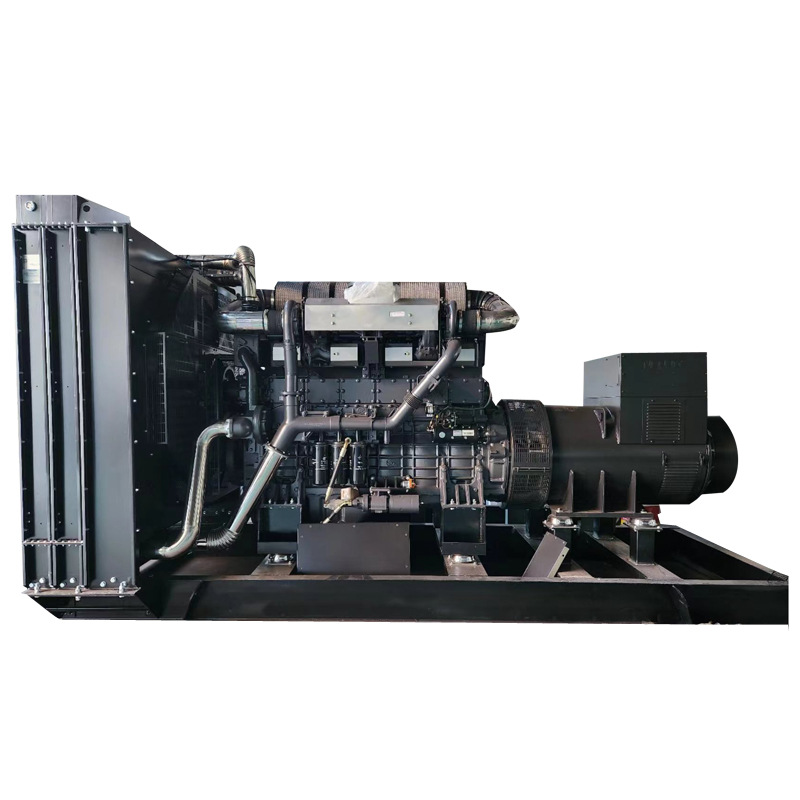

sdec generator set manufacturers

SDEC generator set manufacturers are leading innovators in power generation solutions, specializing in the production of high-performance diesel and gas-powered generator sets. These manufacturers combine advanced engineering expertise with state-of-the-art manufacturing processes to create reliable power generation equipment. Their generator sets are designed to deliver consistent power output across various applications, from industrial facilities to commercial buildings and emergency backup systems. The manufacturing facilities utilize cutting-edge technology and automated production lines to ensure precision assembly and quality control. Each generator set undergoes rigorous testing procedures to verify performance, fuel efficiency, and compliance with international standards. SDEC manufacturers integrate smart monitoring systems that enable real-time performance tracking and preventive maintenance scheduling. These generators feature advanced control panels with user-friendly interfaces, allowing operators to monitor and adjust parameters easily. The products are built with robust components that ensure durability and longevity, even in challenging operating conditions. Additionally, SDEC manufacturers provide comprehensive after-sales support, including technical assistance, spare parts availability, and maintenance services, ensuring optimal performance throughout the generator's lifecycle.