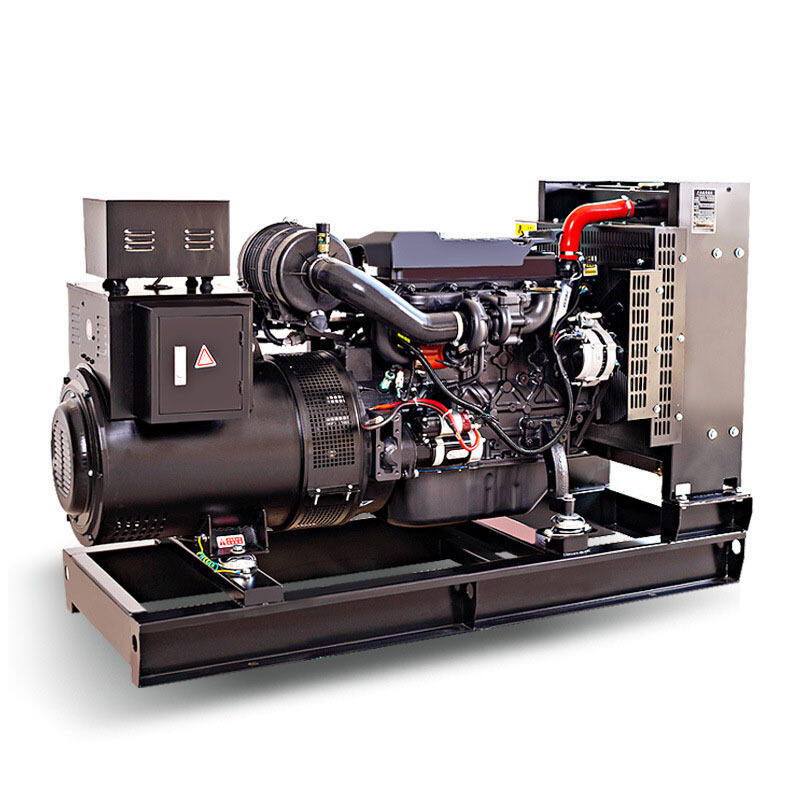

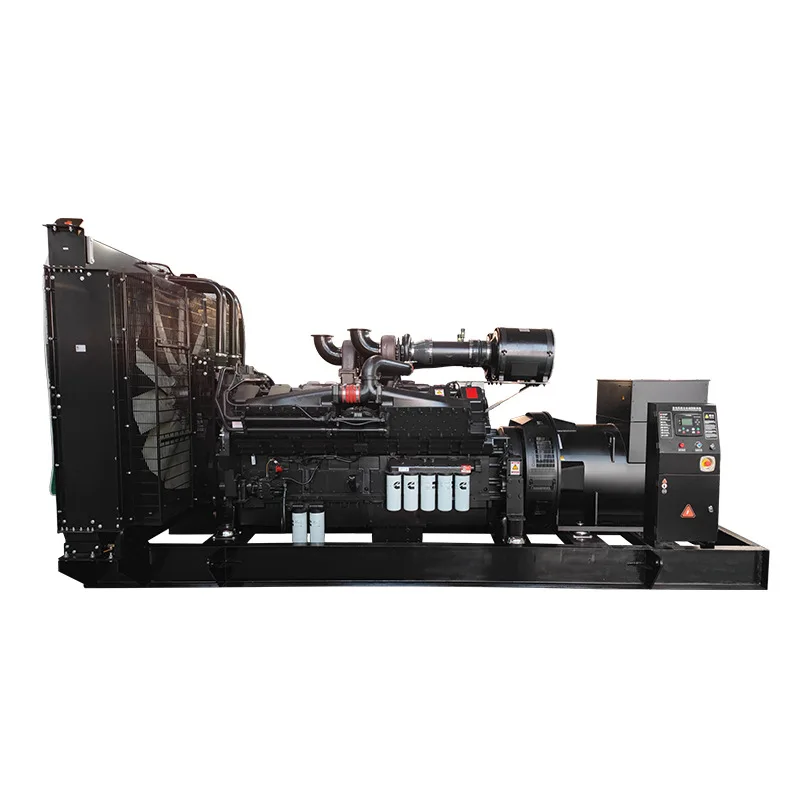

በቀን የሚታየው ተገናኝቶ ያለው ዓለም፣ የኤሌክትሪክ ኃይል መቋረጥ የንግድ ሥራዎችን ሊያስከተል፣ የደህንነት ስርዓቶችን ሊገድብ፣ እና ትልቅ የፋይናንስ ነዳጅ ሊፈጥር ይችላል። በተለያዩ ኢንዱስትሪዎች ውስጥ ያሉ ድርጅቶች የተጠበቀ የኃይል መቆጣጠሪያ መፍትሄዎች አስፈላጊነት በመጨረሻ ይገነዘባል። የአስተማማኝ ኃይል አማራጮችን ሲገሩ፣ ኩሚንስ ግቤ ማሽን (Generator Set) የተረጋገጠ ሞገድነት፣ የተሻለ ሙያዊ ነባሪነት እና የተጠናቀቀ የእገዛ ስርዓት የሚያዋህድ ከፍተኛ ምርጫ ነው። የዚህ ዓይነት የኢንዱስትሪ ደረጃ የኃይል ስርዓቶች የሚስዮን ለመሳሰሉ ጠንካራ መተግበሪያዎች የመጀመሪያ ምርጫ ሆነው ተቆጠረ የትኛውም ጊዜ መቆም አይቻል ወይም አይፈቀድም።

የተመረጠ የኃይል ምንባብ ላይ ካፒታል ማስገደር የሚያስፈልገው የተለያዩ ምክንያቶችን በጥንቃቄ ማሰብ ነው፣ እነሱም ጥራት፣ የነዳጅ ፍላጎት፣ የአገልግሎት ፍላጎት እና ረጅሙ ጊዜ የሚቆይ የአሠራር ወጪ ይገኙበታል። በተመሳሳይ የተሰራ የኃይል ምንባብ ስርዓት ከኤሌክትሪክ መስመር ጥፋት ጋር ባለው ካሬ ያከብራል፣ ስለዚህ ንግድ ይቀጥላል እና ከኃይል ጋር የተያያዘ ጉድለት ከማድረግ ጋር ዋጋ ያለው መሣሪያ ይጠብቃል። የተለያዩ የጄኔሬተር ቴክኖሎጂዎች ዋና ዋና ጥቅሞች እና የቴክኒካል ደረጃዎችን ማወቅ የተወሰኑ የኃይል ፍላጎቶች እና የአሠራር ገደቦች ጋር የሚጣጣሙ ውሳኔዎች ለመውሰድ የሚረዱ ድርጅቶችን ያስችላል።

የኢንጂነሪንግ ልዩ ልዩነት እና የተረጋገጠ ደረጃ

አዲስ እንጅን ቴክኖሎጂ እና ፍላጎት

ኩምንስ የተጠቃሚውን ጥያቄ ለማሟላት በከፍተኛ አፈፃፀም የሚሰሩ የሞተር ቴክኖሎጂዎችን ለመስራት ዓመታት ይዘዋል። የእነሱ የኤሌክትሪክ ጀኔሬተሮች ከፍተኛ ግፊት ያለው የድብልቅ መጥረቢያ ስርዓቶች፣ የተሻሻለ የቁሳቁስ መቀየሪያ ንድፍ እና ኃይል አውታረ መረብን ለመገ tối እና ምላሽ ማስቀነስ ለማግኘት በትክክል የተሰሩ አካላትን ያካተቱ ናቸው። የኩባንያው የአبحራሽ እና ልማት ውስብስብነት የመቆሚያ እና የኃይል ፍጆታ የኢንዱስትሪ ደረጃዎችን ሁልጊዜ የሚያሟላ ወይም የሚበልጥ የሆኑ ሞተሮችን አስቀምጧል።

የእነዚህ ኃይል ሲስተሞች ጥብቅ የሆነ የ конструкци አካሄድ የሚጠቀመው የተረጋጎሙ የኢንዱስትሪ ቦሎኮችን፣ ከባድ ድግሚያ ያላቸው አልተርናቶሮችን እና በከባድ የሚገኙ አካላት ውስጥ ባለው ግሩማ ሁኔታ ለማራዘም የተሰሩ የተሻለ ማዝጋት ሲስተሞችን ይጠቀማል። የተለያዩ ጭነቶች እና የአካባቢ ሙቀቶች መካከል ተስማሚ ልክ ለመስጠት እያንዳንዱ አካል ግለሰብ የፈተኑ ሂደቶችን ያለፍልግ ያለ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያ......

የጥራት ቁጥጥር እና የማምረቻ ደረጃዎች

የማምረቻ ግንባታዎች የማቅረብ ሂደቶችን ከመጀመሪያው በር እስከ የመጨረሻ መሰል ማረሚያ ፍተኛ ድረስ ያለውን ሁሉ የማቅረብ ሂደት የሚከታተሉ የጥራት ዋስትና ፕሮግራሞችን ያተኩራሉ። ከአካላቱ ግቤት ከፍተኛ የሆነ የመጨረሻ ምርመራ እስከ የመጨረሻ ምርመራ ድረስ፣ እያንዳንዱ ግенератор ስብስብ የተቀመጠ የሆነ የጥራት መለኪያ ነጥቦችን ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለፍልግ ያለ......

የራስ ቁጥጥል የሚሆኑ የፈተና መሣሪያዎች እና የኮምፒዩተር የሚቆጣጠሩ የማሰልጫ ሂደቶች የሚያስተዋሉት ሰው ልጅ ስህተት ሲቀንሱ ህዋሳዊ አካላት ላይ ግድ ያላቸው የመጠን ገደቦች ይቆያሉ። የፋብሪካ እርባታ ፈተና ሂደቶች አሃዝ ላይ የሚገቡበትን ሁኔታዎች ይፈተናሉ ከዚያም አሃዞቹ ለደንበኞች ይላካሉ። ይህ ጥልቅ ፈተና ስርዓት እያንዳንዱ ጃነሬተር በእውነተኛ ኃይል አደጋዎች ጊዜ የሚጠራ ጊዜ በተረliable ሁኔታ ይሰራል የሚለውን ጥሩ ምስክርነት ይሰጣል።

የĐTል አስተዳደር እና የአካባቢ አስተዳደር

የተመቼ ስብር እና የተለቀፈ ቁሳቁስ ቁጥጥር

ሞዴርን ዲዛል ግማሽ ቴክኖሎጂ የተሻሻለ ሆነ ከአካባቢ ጋር የተያያዘ ጥላ ማስቀረት ሲገዙ ምርታማ የውሃ ክፈፍን በተመሳሳይ ሁኔታ ያቆያል። የሙቅ መጠጥ ጊዜ፣ የኤሌክትሮኒክ ሞተር መቆጣጠሪያዎች እና የአየር አስተዳደር ስርዓቶች የእሳት ፍላጎትን ለመከፋፈል እና የሚያሳዝኑ ሃይድሮ ካርቦናቶችን ለመቀነስ አብረው ይሰራሉ። ይህ የቴክኖሎጂ ማሻሻያ የተቋማትን የአካባቢ መስፈሮችን ሳይቀንሱ የሥራ አፈጻጸም ማግኘት ያስችላል።

የተመረጡ መምታት ምላሽ ስርዓቶችን እና ዶሴል ቅንጣቶችን ማስቀመጥ የአካባቢ ተጽእኖን ይቀንሳል ሲሆን ቢያንስ የነዳጅ ባህሪያትን ያቆያል። የሞተር አስተዳደር ስርዓቶች የሚሰሩበትን ሁኔታ በተግባር ይከታተላሉ እና ለተለያዩ ጭነቶች በጣም ጥሩ እንዲሆን የነዳጅ አቅርቦት በራሱ ይስተካከላል። ይህ የገለልተኛ መቆጣጠሪያ አቀራረብ የነዳጅ ፍላጎት በጣም ጥሩ እንዲሆን ያደርጋል ሲሆን የአይ템 ጥገና ፍላጎትን ያነሳስራል እና የአካላት ዕድሜን ያረጋግጣል።

የክፈል ዋጋ አስተሳሰብ

የውሃ ክፈፍ ረጅም ጊዜ የሚቆይ የአሰራር ክፍያዎችን በቀጥታ ያነፀባርቃል፣ ስለዚህ የማመንጪ ምርጫ ስልተ-ቀመቶች ውስጥ ዋና ማስታወሻ ይሆናል። ከዋናው ክፍያ በላይ በኪሎواት-ሰዓት የሚፈጠር የተሻለ የውሃ ክፈፍ ያላቸው ሞተሮች በረጅም ጊዜ የሚቆዩ ሆኑ ትልቅ የገንዘብ ችሎታዎችን ያስገኛሉ። የተሻለ የውሃ መርከቢያ ቴክኖሎጂ እና የተሻለ የሞተር ጊዜ ማጣመር የውሃ ፍጆታ መጠን ብዙ ጊዜ የኢንዱስትሪ አማካይ ዋጋ በከፍተኛ መጠን የሚበልጡበት ይሆናል።

በረጅሙ ጊዜ የሚቆዩ አገልግሎቶች እና በቀላሉ የሚገኙ የተለወጡ ክፍሎች የአገልግሎት ክፍያዎችን የሚቀንሱ ስርዓቶች የאיכות የኃይል ማመንጫዎችን የኢኮኖሚ ጥቅሞችን ይጨምራሉ። የተሻለ የመከታተል ስርዓቶች የሚፈቅዱ የቀደመ-ገመተ አገልግሎት አቅም ድርጅቶች የአገልግሎት እንቅስቃሴዎችን በተզጋጀ አልቦታ ጊዜ ለማስቀመጥ ያስችላቸዋል፣ የአደገኛ ግንባታ ክፍያዎችን ይቀንሳል እና የአሰራር ግድያዎችን ይቀንሳል።

የመተግበሪያ ግለሰብነት እና የጭነት አስተዳደር

ሚዛናዊ የኃይል መፍትሄዎች

የተለያዩ የአንድ ነጥብ ግዟሽ ፍላጎቶችንና የስፋት ዕቅዶችን ለማሟላት የኢንዱስትሪ መተግበሪያዎች የመርከብ ኃይል መፍትሄዎችን ይፈልጋሉ። የጄነሬተር ስብስቦች ከታካሚ የንግድ ᒪሣኞች ጀምሮ ሙሉውን የផለጋሽ ግዟሽ ግዴታዎች ለማሳደግ የሚችሉ የኢንዱስትሪ ድረስ የተለያዩ የኃይል ክልሎች ውስጥ አሉ። ይህ የሚዛመደው መጠን ያለው የኃይል መቆጣጠሪያ የአሁኑ ፍላጎቶችን ለማሟላት ተስማሚ መጠን ያላቸውን መሣሪያዎች ለመምረጥ እንዲሁም የወደፊት የኃይል አቅም ማስፋፋት አማራጮችን ለማግኘት የሚያስችል ነው።

የተመረጡ የጀነሬተር ስብስቦች አብረው መስራት የሚችሉበት ባህሪያት ሁለቱንም የገቢ ኃይል ማቅረብ እና የጭነት ክፍፍል ጥቅሞችን ያቀርባል። ይህ የማሰራጃ አቀራረብ የጨረታ የኃይል ማቅረብ እና በገቢ አቅም በኩል የተሻለ የሲስተም ጥራት አስተዋጽኦ ያስችላል። የተመረጡ የጭነት አስተዳደር ሲስተሞች በራሳቸው የተለያዩ መሣሪያዎችን ይመራሉ ምክንያቱም የነዳጅ ቅሪትነት ለማ tốiመዝገብ እና ሁሉም የሚሰሩ ጀነሬተሮች ላይ የተመታጠነ የጭነት ክፍፍል ለማረጋገጥ ነው።

የኢንዱስትሪ የተወሰኑ የማሰራጃ ቅጦች

የተለያዩ ኢንዱስትሪዎች የባለሙሉ ግንኙነት ያላቸው የኃይል ምርት ፍላጎቶች አሏቸው ይህም የተለያዩ የጄነሬተር መዋቅራዊ ቅደም ተከተሎችን ያስፈልጋል። የጤና ግብአቶች በፍጥነት መጀመር የሚችሉ እና ያለ ችግር ማዛመጃ የሚያስችሉ የማይገድዱ ስርዓቶችን ያስፈልጋሉ። ዳታ ማቆሚያዎች የተቀናጀ የእንጅ ባህሪ እና የተቀናጀ የማስተዋል አቅም ያላቸው የኃይል ስርዓቶችን ያስፈልጋቸዋል እንዲሁም የተቀናጀ ኦፕሬሽን ፍላጎቶችን ያስተማማሉ።

የផabrication ኦፕሬሽኖች ብዙውን ጊዜ የሚያስፈልጋቸው የኩምኒ ጀነሬተር ስብስብ የሚቻልበት የሞተር መጫኛ ጭነቶችን እና የተለያዩ የኃይል ፍላጎቶችን የሚችል የሆነ መዋቅር ነው። የሚቀየር የቆጣሪ ስርዓቶች እና የተለያዩ የአልተርናተር ዲዛይኖች እነዚህን የጄነሬተር ስርዓቶች የሚፈለገውን የኤሌክትሪክ ባህሪ ለመገኘት ያስችላሉ እና ለአስፈላጊ የኢንዱስትሪ መሳሪያዎች ያስተማማሉ።

የመረመሪያ እና ድጋፍ መዋቅር

አምባለንተ መስራት ተመሳሪያዎች

ጠንካራ አገልግሎት እና ድጋፍ የሚሰጠው ሐይል መርሃ ግብፅ ሲስተሞች የሚያስፈልጉትን መጠበቂያ እና በጊዜው ጊዜ ጣሪፍ አገልግሎቶች ለማረጋገጥ ያስችላል። የተለያዩ የሸያጭ ዩኒታቸው የአካባቢ ቴክኒካዊ እውቀት እና የ spare parts አቅም ያቀርባል፣ ይህም የመቆየት ጊዜውን ያቀንሳል። ከሙከራ ቤት ጋር የተመዘገቡ ቴክኒሻኖች የተለያዩ የጄኔሬተር ሞዴሎች የሚያስፈልጉትን ዝቅተኛ ዝርዝር ግድ ያውቃሉ እኔ ምሁራን የአገልግሎት ማመልከቻዎችን ይሰጣሉ።

የርቀት ክትትል ችሎታዎች ለጥገና መርሃግብር እና ለስርዓት ብልሽቶች ከመድረሳቸው በፊት ሊከሰቱ የሚችሉ ችግሮችን ቀደም ብሎ ለመለየት ያስችላሉ። የተራቀቁ የምርመራ ስርዓቶች የመኪናውን መለኪያዎች፣ የኤሌክትሪክ ኃይል ማመንጫ ባህሪያትንና የአሠራር ሁኔታን ያለማቋረጥ በመከታተል ችግሮችን ሊያመለክቱ የሚችሉ አዝማሚያዎችን ለመለየት ይሞክራሉ። ይህ የጥገና ዘዴ ድርጅቶች ያልተጠበቁ ውድቀቶችን እንዳይገጥሙና የጥገና ወጪዎችን እንዲያመቻቹ ይረዳቸዋል።

የኩነቶች የመገኛ እና የቴክኒካዊ ድጋፍ

አጠቃላይ የክፍሎች ክምችት ስርዓቶች ለመደበኛ ጥገና ወይም ለአደጋ ጊዜ ጥገና አስፈላጊ በሚሆንበት ጊዜ የሚተኩ ክፍሎች በቀላሉ እንዲገኙ ያረጋግጣሉ። በበርካታ የጄነሬተር ሞዴሎች ውስጥ ደረጃውን የጠበቁ የክፍሎች ዲዛይኖች የክምችት አስተዳደርን ቀላል ያደርጉታል፣ የክፍሎች ወጪዎችን በመጠን ኢኮኖሚዎች ይቀንሳሉ። ዝርዝር የአገልግሎት መመሪያዎችን፣ የመላ ፍለጋ መመሪያዎችን እና የመስመር ላይ የምርመራ መሳሪያዎችን ጨምሮ የቴክኒክ ድጋፍ ግብዓቶች የጥገና ሰራተኞች የአሠራር ችግሮችን በፍጥነት እንዲለዩ እና እንዲፈቱ ያግዛሉ።

የሙርجة ድጋፍ አገልግሎቶች ውስብስብ የሆኑ የጥገና ሂደቶች እና የሲስተም ኦፕቲማይዛሽን ፕሮጀክቶች ለተጨማሪ እውቀት ያቀርባሉ። ለደንበኛ የጥገና ሰራተኞች የተዘጋጁ ስልጠናዎች ድርጅቶች የውስጥ አቅሞችን ለማድረግ እና አገልግሎት እንቅስቃሴዎች ከየት እንደተሰሩ መሐንዲስ ደንቦች እና የደህንነት ፕሮቶኮሎች መሠረት እንዲከናወኑ ያስችላል።

የቆጣሪ ሲስተሞች እና አውቶሜሽን

የተሻለ የማስተዋል እና የቆጣሪ ባህሪያት

ዘመናዊ የማፍራይ ቁጥጥር ሲስተሞች የሚያሳዩ የሙከራ አቅሞችን ያካተቱ ሲሆን ይህም በአፈፃፉ እና በክዋኔ ሁኔታ ላይ በትክክል የሚታይ ንድፈ ሐገር ይሰጣል። የዲጂታል የማሳያ መገለጫዎች ዋና ዋና የሆኑ የእንቅስቃሴ መለኪያዎችን በተጠቃሚ ግልጽ ቅርጸት ይቀርባሉ፣ ሲ meanwhile የውሂብ መዝገብ አቅም የታሪክ ማስታወሻዎችን ለዝርዝር ትንተና እና ለግንባታ ዕቅድ ማረጋገጫ ያቀርባል። የተሻሉ የመቆላል ሲስተሞች ማዕከላዊ የመቆላት ክፍሎች ውስጥ ካሉ ኦፕሬተሮች የማፍራይ ሲስተሞችን ማ Quar እንዲችሉ የሚያስችሉ የተሻሉ የሩራ መቆላት እና የ Quar አቅሞችን ያቀርባሉ።

በኤሌክትሪክ ከርፈት ጊዜ የራስ ቁጥጥር የማዛወሪያ ማቀፊያ የኃይል ማዛወሪያውን በኤሌክትሪክ እና በማፍራይ መካከል ምንም ልዩነት የሌለው ይሁን ያረጋግጣል። የተቋቋሙ የጭነት አስተዳደር ተግባሮች ዋና ዋና የሆኑ ጭነቶችን ለማስተዋል እና በረጅም ክዋኔ ጊዜ ጭነት ማስወገጃ ስልቶችን ለመተግበር ኦፕሬተሮችን ያስችላል። የተገለጸው የቁጥጥር አቅሞች የእጅ ግንኙነት ፍላጎቶችን ያነሱ ሲሆን በተመሳሳይ ጊዜ የሲስተም አፈፃፉን እና የነዳጅ ፍላጎትን ያ tối ያደርጋል።

ከየታደረ አስተዳደር ስርዓቶች ጋር የተዋሃደ

የአሁን ያለው የአንድ ማዕከን አስተዳደር ስርዓቶች ጋት ያለው የማዋሃድ አቅም የተመለስ የኃይል ስርዓቶችን ከሌሎች የዋና የመሠረታዊ መቃዐን አካላት ጋር ማተን እና ማስተን ያስፈልጋል። የተ станд የኰመኝኩን ግንኙነት ፕሮቶኮሎች የጀነሬተር ስርዓቶች ከዕቅድ አስተዳደር የሶፍትዌር ፕላትፎርሞች ጋር የአሠራር ዳታ እንዲጋራ ያስፈልጋል፣ የኃይል ስርዓት አፈፃፀም እና ሁኔታ ስለ ያለው ግን ሙሉ እይታ ያቀርባል።

የአላማ እና የማስጠን ስርዓቶች የጀነሬተር ስርዓቶች ላይ ያስፈልጋቸው ሲሆን ወይም የአሠራር ግብዓቶች የተቋቋ ደዚማ ገደቦችን ሲያልፍ የአንድ ጊዜ ማስጠን ያቀርባሉ። የእነዚህ የራስ የማስጠን አቅሞች ትክክለኛ ሠራተኞች የስርዓት ሁኔታ ለውጦች በትንሣኤ እንዲታወቁ ያስፈልጋል፣ ለተፈጠረ ችግሮች በፍጥነኛ መልስ እንዲሰጥ እና የተሻለ የስርዓት ጥራት እንዲቆይ ያስፈልጋል።

የመጫኛ እና የመጀመሪያ ነገዶች

የአካባቢ መዘጋጃ እና የመሠረታዊ መቃዐን የሚፈልጉ ነገዶች

የማመን ትክክለኛ አሰልጠኛ የሚያስገድደው ማመን አፈፃፀም እና ረጅም ጊዜ የሚቆይበት ነው። የአካባቢ ማዘጋጀት የሚכלולባቸው ሰንጠረዥ አቀራረብ፣ የነዳጅ ሲስተም አሰልጣኝ እና የኤሌክትሪክ ግንኙነት አቅርቦት ነው ይህም የአካባቢው ኮዶች እና የሙከራ መጻፍ መስፈርቶች መከተል አለበት። ረጅም ጊዜ የሚሠራበት ጊዜ የሚፈለገውን የሙቀት መጠን ለማቆየት ተስፋ የሚደረገው በታዘዙ እና በታዋቸው አየር ነው።

የነዳጅ ማከማቻ ሲስተም አቀራረብ የሚፈለገውን አቅም፣ የአካባቢ ᆳጭታ እርምጃዎች እና የማስረግያ ኃላፊነቶች መመልከት አለበት። ሥር እና ላይ ያሉ ማከማቻ አማራጮች እያንዳንዱ የተወሰኑ ጥቅሞች እና አሰልጣኞች አሉላቸው ይህም በአካባቢው ገደቦች እና የአካባቢው ደንቦች ላይ ከተመለከተ መገምገም አለበት። ትክክለኛ የነዳጅ ሲስተም አቀራረብ ፍልትሬንግ፣ የማስተላለፊያ ጫመታዎች እና የነዳጅ ጥራት እና የማቅረብ ሁኔታ ለማረጋገጥ የሚያስችሉ ማስታወቂያ ሲስተሞችን ያካትታል።

የፈተና እና የማረጋገጫ ሂደቶች

የተጠናቀቁ የመጀመሪያ ማረሚያ ሂደቶች ሁሉንም የ המערכת አካላት የተሰሩበት መለኪያዎች እና የአፈፃፀም ያስፈልጋቸው ሁኔታዎች መሟላታቸው ይፈልጋል። የባንክ ጭነት ፈተና የማመንጫ አቅም እና የአፈፃፀም ባህሪያት በሙሉ የሚפעלበት ክልል ውስጥ ያረጋግጣል፣ ተራ ማዞሪያ ፈተና ደግሞ በማያያዝ ኃይል የቆመበት ሁኔታ ላይ ትክክለኛ አውቶማቲክ አሰራር ያረጋግጣል።

የአፈፃፀም ማረጋገጫ ፈተና የተቀመጠው የአሰራር መለኪያዎች ለቀጣይ ጥገና እና ለችግር መፍታት የሚያገለግሉ የማጣቀሻ ነጥቦች ያቀርባል። ይህ የመጀመሪያ የአፈፃፀም መለኪያዎች የሲስተም ዝውውር ላይ በጊዜ ላይ የሚከሰተውን መቀነስ ማየት እና የተመቻ አፈፃፀም ደረጃዎች ለመጠበቅ ጊዜ ሲጠየቅ ጥገና እንዲደረግ የሚያስፈልገውን ዋጋ ያለው መረጃ ያቀርባል።

ተደጋጋሚ ጥያቄዎች

የማስተናገድ ጅኔሬተር ሲስተም መጠን ሲቆጠር ምን ምክንያቶች መጠን መብለጥ አለባቸው

ጂነሬተር መጠን ማወቅ የሚያስፈልገው የኤሌክትሪክ ጭነት ዝግጅቶችን በአቀራረብ እና በዘመናዊ ጭንቀቶች (ለምሳሌ የሞተር መጀመሪያ የቃል ፍሰት) ላይ ያለ ጥሩ ትንተና ነው። የኃይል መቆራረጥ ጊዜ ላይ ማቆሚያ የሚደርስ የመጨረሻ ጭነቶች ማወቅ እና ቅድሚያ ማግኘት አለባቸው እና አነስተኛ የችሎታ ዝግጅቶች ለማወቅ ያስፈልጋል። የወደፊት መширение ዝግጅቶች እና የጨረታ ግንዛቤ ግንዛቤዎች ደግሞ ለረጅም ጊዜ ተስማሚ የሆነ የችሎታ መጠን ለማረጋገጥ መጠን ይኖራል። የሙያ ጭነት ትንተና የከፍታ የሚፈልግ ጊዜያትን እና የተገናኘው ጭነት ጠቅላላ ከየትኛው የኃይል ዝግጅት ጋር የተያያዘ የሚሆን የተለዩ ምክንያቶችን ለመለየት ያስችላል።

የእረዳታ ጂነሬተሮች ምን ያህል በየጊዜው መፈተሽ እና መጠበቅ አለባቸው

የመደመር ማረጋገጫ የሚከናወኑበት ጊዜ በተለምዶ የአራት ሺዋ ሰዓት ውስጥ ያልተጫነ ሁኔታ ላይ የሚካሄዱ ማረጋገጫዎች እና የወር የእውነተኛ ጭነት ሁኔታ ላይ ያሉ ሙከራዎች ናቸው ። ዓመታዊ ጥብቅ ሙከራዎች ረጅሙን ጊዜ የሚቆዩ ሙሉ ጭነት ኦፕሬሽኖችን መካተት አለባቸው ። ይህ ግድፈቶች ወደ አስፈላጊ ድክመቶች ሲቀሩ ቀድሞ ሲያሳይ ይረዳል ። የማስተናገድያ ዘመናት በሚሰራበት ሰዓት እና በአካባቢው ሁኔታዎች ላይ የተመሰረተ ሲሆን አጠቃላይ ህይወት የሚቆይበትን ጊዜ ለማረጋገጥ በተወሰኑ ዘመናት የሚከናወኑ ነገሮች የሚካተቱ ነው ። ቀድሞ የሚከናወኑ የማስተካከያ ፕሮግራሞች የተገቢውን ኦፕሬሽን ለማረጋገጥ እና የציוד የአገልግሎት ጊዜ ረጅሙን ጊዜ ለማድረግ ይረዱናል ።

የአስተማማኝ እና ዋና የኃይል መጠኖች መካከል ያሉ ዋና ልዩነቶች ምንድን ናቸው

የአደጋ ጊዜ ሞተር አቅም የሚያገለግልበት ሁኔታ የኤሌክትሪክ አቅርቦት ሲቋረጥ በተወሰነ ጊዜ ለተለያዩ ግስጋሴዎች ሲሆን፣ የፕራይም ኃይል መጠን ደግሞ ዋና የኃይል ምንጭ ሆኖ በማይቆመው ሁኔታ ከከፍተኛ አቅም ጋር ያለ ገደብ የመጠቀሚያ ጊዜ ያለው ሲሆን፣ የአደጋ ጊዜ ሞተር በአጭር ጊዜ የበለጠ ኃይል ይሰጣል፣ የፕራይም ሞተር ደግሞ በታችኛ ደረጃ ሃይል ላይ ረጅሙ ጊዜ ይቆያል፣ በተሻለ የድንጋይ ነዳጅ ፍላጎት እና ረጅሙ የቴክኒካዊ ግንባታ ጊዜ ጋር ይሰራል።

የሞተር አሰልጣትና አፈጻጸም ላይ የሚነሳው የአካባቢ ጉዳዮች ምንድን ናቸው

አካባቢ ሁኔታዎች የአካባቢ የሙቀት መጠን፣ ማመልከቻ በሞተር ግብረ ሰላም ላይ ያሳድረው ተጽእኖ እና ምንጭ የሆኑ መስዋዕትን ለመቃወም የሚያስፈልጉ የተለየ የ 보호 እርምጃዎች ሊያካትቱ ይችላሉ። ድብቅ ደንቦች ድብቅ የማቀነሻ ስህተቶች ወይም የማህበረሰብ ተጽእኖ ለማጣራት የሚያስፈልጉ የ strategically አቀማመጥ ሊያስፈልጉ ይችላል። የወፍ መስሪያ ደንቦች በአካባቢ ላይ የተመሰረተ ሊለያዩ ይችላሉ እና የወሽ ስርዓት አቀማመጥ እና የአካባቢ ማስተዋል ውል ያካትታሉ የጄነሬተር ፍለጋ እና አሰልጣጥ ይገድባሉ። የነዳጅ ማከማቻ እና የማቆሚያ ስርዓቶች ከብረታ, የውሃ ማስፋፋት እና የውሃ ማስወገጃ ጋር ለማተኩር የአካባቢ ጥበቃ ደንቦች መከተል አለባቸው።