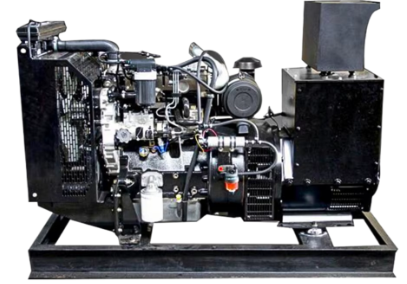

የምሳሌ ማረጋገጫ የፐርኪንስ ጀነሬተር ስብስብ ድምር

እንደምን የግንባት ድምር እfficency የሚያስፈልግ ነው

ነገሮችን በብቃት ለማከናወን ትክክለኛውን መጠን ያለው ጀነሬተር ማግኘት በጣም አስፈላጊ ነው። የጄኔሬተሩ መጠን ከትክክለኛው ፍላጎት ጋር የሚስማማ ከሆነ በአጠቃላይ የተሻለ ይሰራል። በጣም ትንሽ መሆን ማለት በመንገድ ላይ ያለማቋረጥ ከመጠን በላይ ጭነት እና ብልሽቶች መቋቋም ማለት ነው። በሌላ በኩል ደግሞ ከመጠን በላይ መጠኑ እየጨመረ ሲሄድ ነዳጅ ያባክናል፤ እንዲሁም ከሚያስፈልገው በላይ ልቀት ያስከትላል። ተገቢውን መጠን ያላቸው ጄኔሬተሮች በኢንዱስትሪው መረጃ መሠረት የነዳጅ ወጪን ወደ 30% ይቆጥባሉ ። እነዚህ ቁጠባዎች በቀጥታ ወደ ዝቅተኛ ወጪዎች እና አነስተኛ የአካባቢ ተፅዕኖ ይተረጎማሉ፣ ይህም በአሁኑ ጊዜ ከአረንጓዴ ተነሳሽነት ጋር በጥሩ ሁኔታ ይጣጣማል። ተገቢውን የጄኔሬተር መጠን መምረጥ የፐርኪንስ መሣሪያዎች ውጤታማነት ላይ ትልቅ ለውጥ ያመጣል እንዲሁም ገንዘብ ሳያባክን ወይም አካባቢውን ሳይጎዳ የሀብት ፍጆታን በቁጥጥር ስር ለማዋል ይረዳል።

የተመለከተ ጥንታይ ቀስት እና የተመለከተ ጥንታይ ቀስት ውስጥ ያሉ አስፈላጊ አቀፍ ደረጃዎች

ትክክለኛውን መጠን ያለው ጀነሬተር ማግኘት ለማንኛውም የንግድ ሥራ በጣም አስፈላጊ ነው። ኩባንያዎች በጄኔሬተር አቅማቸው ከመጠን በላይ ሲጠቀሙ ለአገልግሎት እና ለነዳጅ ተጨማሪ ገንዘብ በመክፈል ወደ አየር ውስጥ አላስፈላጊ ብክለትን ያወጣሉ። በሌላ በኩል ደግሞ በጣም ትንሽ መሆን ማለት በሥራ የበዛባቸው ጊዜያት ውድ ማሽነሪዎችን በጊዜ ሂደት ሊያቃጥሉ የሚችሉ የቦውንውት አደጋን ያስከትላል ማለት ነው። ብዙዎቹ የፋብሪካ አስተዳዳሪዎች የተሳሳተ የመጠን ውሳኔዎች ከብዙ ወራት በኋላ እንዴት እንደሚጎዱ አይተዋል። ለምሳሌ አንድ ፋብሪካ ለዕለት ተዕለት ፍላጎቶች በጣም ኃይለኛ ወይም በቂ ያልሆነ የፐርኪንስ ጀነሬተር ስብስብ ካዋቀረ በረጅም ጊዜ ውስጥ ጥሩ አፈፃፀም አይኖረውም። ለዚህም ነው በተለያዩ ወቅቶች ውስጥ ያለውን ትክክለኛ የኃይል ፍጆታ ንድፍ ለማስላት ጊዜ መውሰድ በጣም አስፈላጊ የሆነው ። የቤት ውስጥ ሥራዎች

የโหลด ቅጥር አስፈላጊ ነፃነት ለ Perkins generators

የጠቅላላ አ菁ታ ቅጥር አንድ ነጥብ ነጥብ

የፐርኪንስ ጀነሬተር መጠን ከመምረጥዎ በፊት አጠቃላይ የኃይል ፍላጎቱን ማሟላት ሁሉንም ለውጥ ያመጣል። ይህ ሂደት የሚጀምረው በቦታው ላይ የሚሰራውን ነገር ሁሉ በመገምገም እና እነዚህ ከፍተኛ ጭነቶች ምን ሊሆኑ እንደሚችሉ በመለየት ነው። የኤሌክትሪክ ኃይል የሚጠቀሙ ማሽኖችን፣ መሣሪያዎችንና ሌሎች ነገሮችን በዝርዝር ጻፍ፤ ከዚያም የኤሌክትሪክ ኃይል ምን ያህል እንደሆነ በዝርዝር ጻፍ። እነዚህን ሁሉ ቁጥሮች ካገኘን በኋላ፣ በአጠቃላይ ምን አይነት ኃይል እንደሚያስፈልገን ለመገመት እነሱን አንድ ላይ እንጨምራለን። አብዛኛዎቹ የጄኔሬተር ኩባንያዎች በአሁኑ ጊዜ የተወሰኑ ግምቶችን የሚያስወግዱ አነስተኛ የሂሳብ መሳሪያዎችን ያቀርባሉ ። ይህንን በትክክል ለማድረግ ጊዜ መውሰድ የተመረጠው ጀነሬተር በኋላ ላይ ባልተጠበቁ ፍላጎቶች ውስጥ አይታገልም ማለት ነው ፣ በነዳጅ ወጪዎች ላይ ገንዘብ መቆጠብ እና በወሳኝ ክዋኔዎች ወቅት ጀነሬተሩ ከመጠን በላይ የሚጫንበትን ሁኔታ ማስወገድ ።

የጀምሮ እና የአስተካክል ዩዋት በመለያ የተለያዩ

የኤሌክትሪክ ጭነት ሲሰላ ሰዎች ብዙውን ጊዜ የሚያቃልሉት ነገር ቢኖር በመነሻ ዋት (የማመንጫ ዋት ተብሎም ይጠራል) እና በመደበኛ የስራ ዋት መካከል ያለው ልዩነት ነው። በሞተር የሚንቀሳቀሱ መሣሪያዎች ለመጀመሪያ ጊዜ ሲበሩ ተጨማሪ ኃይል ያስፈልጋቸዋል፤ አንዳንድ ጊዜ በተለመደው አሠራር ጊዜ ከሚጠቀሙት ኃይል ሁለት ወይም ሦስት እጥፍ እንኳ ያስፈልጋቸዋል። ለምሳሌ አየር ማቀዝቀዣዎችን እንውሰድ እነሱም ከመነሻው ጀምሮ ከፍተኛ የኃይል ፍለጋን ያቀርባሉ ይህ ደግሞ ለቀዝቃዛ ማቀዝቀዣዎችም ይሠራል። ይህንን በትክክል ማድረጉ አስፈላጊ ነው ምክንያቱም እነዚህን የመጀመሪያዎቹን ጫፎች ካላገናዘብን ጄኔሬተሮች በጭነት ስር ሊታገሉ ወይም ሙሉ በሙሉ ሊወድቁ ይችላሉ ። ይህንን ጽንሰ ሐሳብ በትክክል መረዳት ጄኔሬተሮችን በትክክል እንድናስቀምጥ ይረዳናል ስለዚህ ያለመጨናነቅ ወይም አላስፈላጊ የኃይል ማባከን ውጤታማ በሆነ መንገድ ይሰራሉ።

የአንድ-ፊዚ እና የ셋-ፊዚ ውሃ ያለበት ደ gratuits

ለሥራው ትክክለኛውን የፐርኪንስ ጀነሬተር በመምረጥ ላይ ነጠላ-ደረጃን ከሶስት-ደረጃ ኃይል ፍላጎቶች የሚለየው ምን እንደሆነ ግልጽ ማድረግ በጣም አስፈላጊ ነው ። አብዛኛዎቹ ቤቶች በአንድ ምዕራፍ ላይ በሚሰራ ኤሌክትሪክ የሚሠሩ ሲሆን ይህም መብራቶች፣ ትናንሽ መገልገያዎች፣ ምናልባትም አንድ ወይም ሁለት አየር ማቀዝቀዣዎች ላይ ጥሩ ውጤት ያስገኛል። ግን ኢንዱስትሪዎች ሙሉ ለሙሉ የተለየ ታሪክ ይናገራሉ። የሶስት ምዕራፍ ስርዓቶች የተሻለ ሚዛን እንዲኖራቸውና ከጊዜ ወደ ጊዜ ይበልጥ ብልህ ሆነው እንዲሰሩ ያደርጋሉ፤ ይህም ፋብሪካዎችና መጋዘኖች ቋሚ ኃይል ለሚያስፈልጋቸው ትላልቅ ማሽኖች ሁሉ በእነዚህ ላይ በጣም የሚተማመኑበትን ምክንያት ያብራራል። በአሁኑ ጊዜ በማንኛውም የማምረቻ ተቋም ላይ ይመልከቱ እና እድሉ ጥሩ ነው እነሱ በጠቅላላው ሶስት-ደረጃ ሽቦዎች አሏቸው ምክንያቱም ብዙ ጊዜ ሳይበላሽ ከባድ መሣሪያዎችን ይጠይቃል ። የኃይል ማመንጫዎች ትክክለኛውን ምርጫ ማድረግ ማለት በቂ ኃይል የሌላቸው ወይም አቅም ያጡ አሃዶች ከመያዝ ይልቅ አስፈላጊ በሚሆንበት ጊዜ አስተማማኝ ኃይል ማግኘት እና በረጅም ጊዜ ውስጥ ገንዘብ መቆጠብ ማለት ነው።

የተለያዩ አገላለጽ እንቅስቃሴዎች ስለ የተለያዩ አገላለጽ እንቅስቃሴዎች የሚያስተካክሉ እንደ የተለያዩ አገላለጽ እንቅስቃሴዎች የሚያስተካክሉ ነው፣ Perkins Power ውስጥ የተለያዩ አገላለጽ እንቅስቃሴዎች የሚያስተካክሉ እንደ የተለያዩ አገላለጽ እንቅስቃሴዎች የሚያስተካክሉ ነው።

የተለያዩ አገላለጽ እንቅስቃሴዎች ስለ የተለያዩ አገላለጽ እንቅስቃሴዎች የሚያስተካክሉ እንደ የተለያዩ አገላለጽ እንቅስቃሴዎች የሚያስተካክሉ ነው።

የተለያዩ አገላለጽ እንቅስቃሴዎች: የተለያዩ አገላለጽ እንቅስቃሴዎች የሚያስተካክሉ እንደ የተለያዩ አገላለጽ እንቅስቃሴዎች የሚያስተካክሉ ነው።

በግንባታ ቦታዎች ላይ ያለው የኃይል ፍላጎት ከተለመደው አካባቢ በጣም የተለየ ነው፣ ስለዚህ በተንቀሳቃሽ እና በቋሚ ጄኔሬተሮች መካከል መምረጥ የተወሰነ አስተሳሰብ ይጠይቃል። ተንቀሳቃሽ ጄኔሬተሮች ዋነኛ ጥቅም መሣሪያው በመላው ጣቢያ ሲዘዋወር ወይም ሲስፋፋ በቀላሉ የመንቀሳቀስ ችሎታ ነው። በሌላ በኩል ደግሞ ቋሚ ጄኔሬተሮች አብዛኛውን ጊዜ የበለጠ ኃይል ያላቸው በመሆናቸው ትላልቅ ማሽኖችን ያለማቋረጥ ለማሄድ ይበልጥ አመቺ ናቸው። ከሁሉም በላይ አስፈላጊ የሆነው ነገር በጣቢያው ላይ ኃይል እንዴት እንደሚሰራጭ እና ሰራተኞች በየቀኑ ምን ዓይነት መሳሪያዎች እንደሚያስፈልጋቸው ላይ የተመሠረተ ነው። የተለያዩ የግንባታ ሥራዎችን የሚመለከቱ ጥናቶች እንደሚያመለክቱት ወደ ተንቀሳቃሽ ጄኔሬተሮች መቀየር በቀን ውስጥ ለሚለዋወጠው የኃይል ፍላጎት በደንብ ስለሚስማሙ አጠቃላይ ውጤታማነትን ወደ 30% ከፍ ሊያደርግ ይችላል። ቋሚ ሞዴሎች እንደነዚህ ያሉ ሁለገብ ባይሆኑም ለረጅም ጊዜ አስተማማኝ ኃይል ይሰጣሉ፣ በተለይ ለትላልቅ የግንባታ ሥራዎች አስፈላጊ የሆኑት ቋሚ የኃይል አቅርቦት ያለማቋረጥ ሁሉም ነገር እንዲሠራ የሚያደርግ ነው።

የጤና አገልግሎቶች: የተወሰኑ ግንባታ አስተካክል

በጤና እንክብካቤ ተቋማት ውስጥ የመጠባበቂያ ኃይል መኖሩ በእርግጥም አስፈላጊ ነው ሆስፒታሎች በድንገተኛ ጊዜያት ኃይለኛ ሆነው እንዲቀጥሉ በፐርኪንስ ጄኔሬተሮች ላይ ይተማመናሉ፣ ስለዚህ እንደ የልብ መቆጣጠሪያ እና የሳንባ ምትን ማቀነባበሪያ ያሉ ነገሮች መስራት አያቆሙም ምክንያቱም ገመዱ ይዘጋል። እነዚህን ስርዓቶች በሚያዋቅሩበት ጊዜ ሰዎች የተለያዩ ማሽኖች ምን ዓይነት ኃይል እንደሚፈልጉ ማሰብ አለባቸው እንዲሁም ሁሉም ነገር ለቀጣይነት ሥራ የሚሆን ጥብቅ ደንቦችን ማሟላቱን ማረጋገጥ አለባቸው። የዓለም ጤና ድርጅት ሆስፒታሎች ምን አይነት የመጠባበቂያ አቅም ሊኖራቸው እንደሚገባ መመሪያዎችን ያወጣል በተለይ ህመምተኞቹን በሕይወት ለማቆየት እና ወሳኝ በሆኑ አካባቢዎች መብራቶችን ለማብራት አብዛኛዎቹ የሆስፒታል አስተዳዳሪዎች የፐርኪንስ ሞዴሎች ከሌሎች ምርቶች የሚለዩ መሆናቸውን የሚጠይቁትን ሁሉ ይነግሩታል ምክንያቱም እነዚህ ሞዴሎች ምንም ዓይነት እብጠት ሳይፈሱ ከፍተኛ የኃይል ፍላጎቶችን ሊወጡ ስለሚችሉ ነው፣ ይህም ከመጀመሪያው የኢንቨስትመንት ወጪዎች ባሻገር በሕክምና

ዳታ ሂሳብ: IT ማህደር እና የማይነካ ግንባታ መካከል

በሰርቨሮችና በማቀዝቀዣ ስርዓቶች መካከል ያለውን ኃይል ማመጣጠን በመረጃ ማዕከላት ውስጥ በጣም አስፈላጊ ነው፣ የጄኔሬተር ምርጫን ኦፕሬተሮች ስህተት ለመፈጸም የማይችሉበት ነገር ያደርጋል። የፐርኪንስ ጄኔሬተሮች በዲዛይን ውስጥ የተካተቱ ብልህ የጭነት አስተዳደር ባህሪያት ምስጋና ይግባቸውና እነዚህን ከባድ የኃይል ፍላጎቶች ያሟላሉ ። በዚህ ቴክኖሎጂ አማካኝነት የመገልገያዎች አስተዳዳሪዎች የኃይል ፍላጎታቸውን በትክክል ማወቅ ይችላሉ፣ ስለዚህ ጄኔሬተሮች አቅም ሳይበልጡ በቂ ኃይል ያቀርባሉ። የኃይል ውጤታማነትን በተመለከተ ያሉትን ወቅታዊ አዝማሚያዎች ስንመለከት፣ ወደ ተሻለ የጄኔሬተር ስርዓት የሚቀይሩ ኩባንያዎች ብዙውን ጊዜ የአሠራር ወጪዎች ወደ 20% ይቀንሳሉ፣ እንዲሁም አጠቃላይ ሥራቸው በተሻለ ሁኔታ ይሠራል። ከፐርኪንስ አሃዶች ጋር አብረው የሠሩ አብዛኞቹ ሰዎች በቋሚ የኃይል ፍላጎት እና በአደጋ ጊዜ የመጠባበቂያ ሁኔታዎች ላይ ምን ያህል እንደሚሠሩ ይምላሉ፣ የኤሌክትሪክ ሂሳቦችን በማስቀመጥ እና በጣም አስፈላጊ በሚሆንበት ጊዜ እነዚያን ወሳኝ አገልጋዮች በመስመር ላይ በማቆየት።

አካባቢዎችና የግንባታ አቀራረብ

የነጠላ እንርግี እንደሚያስረዳ እና የአካባቢዎች አስተካክል

አካባቢያዊ አሻራቸውን ለመቀነስ ለሚፈልጉ የንግድ ድርጅቶች፣ ጠንካራ የነዳጅ ውጤታማነት እና ልቀትን የሚመለከቱ ግቦችን የሚወጡ ጄኔሬተሮችን መምረጥ ጥሩ ነው። የፐርኪንስ ብራንድ እዚህ ላይ ጨዋታውን አጠናክሮ የጄኔሬተር ሞዴሎችን በማቅረብ ደንቡ የሚጠይቀውን የሚያሟላ ወይም የሚያሸንፍ ነው። የእነሱ ማሽኖች ኩባንያዎች ቀኑን ሙሉ ውጤታማ በሆነ መንገድ እንዲሰሩ በማድረግ አረንጓዴ ሆነው እንዲቀጥሉ ይረዳሉ። ትክክለኛውን ጄኔሬተር ማግኘትም አስፈላጊ ነው። እነዚህ አሃዶች ትክክለኛ መጠን ሲኖራቸው አነስተኛ ነዳጅ የሚጠቀሙ ከመሆኑም ሌላ አነስተኛ ልቀት ያስከትላሉ፤ ይህም የአካባቢ ጥበቃ ደንቦችን በማክበር ረገድ ችግር እንዳይፈጠር ይረዳል። ከቅርብ ዓመታት ወዲህ የፔርኪንስ ሞዴሎችን ይመልከቱ ከቀድሞዎቹ ስሪቶች ጋር ሲነፃፀሩ ልቀትን በትንሹ ለመቀነስ ችለዋል ። ይህ ደግሞ በጣም በሚያስፈልጋቸው ጊዜ አስተማማኝ የኃይል አቅርቦትን ሳይሰጡ ጥብቅ የሆኑ የአካባቢ መመሪያዎችን ለመከተል ለሚሞክሩ ኩባንያዎች በጣም ማራኪ አማራጭ ያደርገዋል።

የአስተሳሰቢ አካላት የአስተሳሰቢ አካላት

የጄኔሬተሮች ጫጫታ በከተማ አካባቢዎች ከፍተኛ ራስ ምታት ሆኖ ቀጥሏል፤ ይህም ብዙ ንግዶች ጫጫታውን ለመቀነስ የሚያስችሉ መንገዶችን እንዲፈልጉ አድርጓቸዋል። አንዳንድ ኩባንያዎች በጄኔሬተሮቻቸው ዙሪያ ድምፅ የማይሰማባቸው ሳጥኖች ይጭናሉ ወይም በቀላሉ ለድምጽ የማይሰማ ሞዴሎችን ይመርጣሉ። እነዚህ ዘዴዎች ሰዎች በሚበዙባቸው አካባቢዎች ጥሩ ውጤት ያስገኛሉ፤ እዚያም የማያቋርጥ የሞተር ጫጫታ ሁሉንም ሰው ያበሳጫል። በአካባቢው የሚኖሩ ሰዎች የሚፈጽሙት ጫጫታ መጠን የሚወሰንበት ሕግ ምን ዓይነት ጀነሬተር እንደሚጫን ትልቅ ለውጥ ያመጣል። ለምሳሌ ፐርኪንስን እንውሰድ፤ ብዙ ኃይል ሳይለግሱ አብዛኛዎቹን የከተማ መስፈርቶች የሚያሟሉ በጣም ጸጥ ያሉ ሞዴሎችን አዘጋጅተዋል። ይሁን እንጂ የመኖሪያ አካባቢዎችን ወይም ሆስፒታሎችን የሚመለከት ማንኛውም ሰው፣ በመተግበር እና በአፈጻጸም መካከል ያለውን ትክክለኛ ቦታ መፈለግ በጣም አስፈላጊ ነው።

የቁጥር የአሸንጋዊ አካባቢ ዝርዝር

የጄኔሬተሮች ሁኔታ አስቸጋሪ በሚሆንበት ጊዜ መስራት ከፈለጉ የጄኔሬተሮች ሁኔታ አስቸጋሪ በሚሆንበት ጊዜ መስራት መቻላቸው በጣም አስፈላጊ ነው። ለምሳሌ የፐርኪንስ ጄኔሬተሮችን እንውሰድ እነዚህ ማሽኖች የተገነቡት ተፈጥሮ የሚጥላቸውን ማንኛውንም ነገር ለመውሰድ ነው ከሙቀት ሞገድ እስከ ቀዝቃዛ ቀዝቃዛ ዝናብ እና እንዲያውም አብዛኛዎቹን መሳሪያዎች የሚያጠጡ ከባድ ዝናብ ። ኩባንያው አንዳንድ ጠንካራ የግንባታ ዘዴዎችን ይመክራል፤ ለምሳሌ ለዝገት የሚቋቋሙ ከባድ የግንባታ መያዣዎችን እና ለዓመታት ለከባቢ አየር ከተጋለጡ በኋላ የማይበላሹ ክፍሎችን ማሰብ ይቻላል። የኢንዱስትሪው ባለሙያዎች ለክፉ የአየር ሁኔታ የተዘጋጁ ጄኔሬተሮችን መምረጥ ለውጥ እንደሚያመጣ በተደጋጋሚ ይናገራሉ። አውሎ ነፋሶች ሲመጡ ወይም የሙቀት መጠኑ በከፍተኛ ሁኔታ ሲለዋወጥ፣ አስተማማኝ የመጠባበቂያ ኃይል መኖሩ የንግድ ድርጅቶች ምንም ዓይነት የአየር ንብረት ቢኖርባቸውም ያለ ምንም ችግር ሥራቸውን እንዲቀጥሉ ያደርጋቸዋል።

የተመለስ የተለያዩ ክፍሎች

የተወሰነ አስተዳደሮች የሚፈጠሩበት ጥያቄ

ትክክለኛውን ጄኔሬተር ለማግኘት የኤሌክትሪክ ስርዓቶችን በደንብ ከሚያውቁ ባለሙያዎች ጋር መሥራት ያስፈልጋል። እነዚህ ባለሙያዎች እኛ ራሳችን የምናስቀምጣቸውን የኃይል ቁጥሮች ሁሉ ይገመግማሉ እናም ስህተቶች በመንገድ ላይ ውድ ራስ ምታት ከመሆናቸው በፊት ይይዛሉ። እምነት የሚጣልበት ሰው ለማግኘት ስትፈልጉ መጀመሪያ የእሱን ማንነት ማረጋገጫዎች መርምሩ። በተለይ ጄኔሬተሮችን ለመጫን ምን ዓይነት ሥልጠና እንደወሰዱ ተመልከቱ። የተለያዩ የሰውነት ክፍሎች ምን ያህል ኃይል እንዳላቸው የሚቻልበትን ዝርዝር መረጃ ሁሉ ስጣቸው። ቤት ወይም ደግሞ በሥራ ላይ ያሉ ሰዎች ቀኑን ሙሉ የሚያስፈልጋቸውን ነገር ማሟላት ይችላሉ። ስለ መደበኛ አጠቃቀም ዘይቤዎች እና አልፎ አልፎ ስለሚከሰቱ የፍላጎት ጭማሪዎች የበለጠ ዝርዝር መረጃ ባገኙ ቁጥር ሁሉም ነገር በትክክል መጨመሩን ማረጋገጥ የተሻለ ስራ መሥራት ይችላሉ ። ብዙ ሰዎች ይህንን እርምጃ በመተው መሰረታዊ ጭነት ለመያዝ የሚቸገሩ ወይም ከመጠን በላይ በመሆናቸው ከሚያስፈልገው በላይ የሚወጡ ጄኔሬተሮች ያገኙባቸውን ብዙ አጋጣሚዎች እናያለን። ዋናው ነጥብ ምንድን ነው? ልምድ ያለው ቴክኒሻን እነዚህን ሁሉ ስሌቶች ሁለት ጊዜ እንዲያረጋግጥ መፍቀድ ጥሩ ልምድ ብቻ አይደለም፣ ከኢንቨስትመንትዎ እሴት ለማግኘት ፍጹም አስፈላጊ ነው።

የአስተዳደር ሁኔታ ለማስተካከል

የጄኔሬተር ማምረቻ ማለት ከጊዜ ወደ ጊዜ ውጤታማ ሆኖ እንዲቀጥል ንግዱ እንዴት እንደሚያድግ አስቀድመው ማሰብ ማለት ነው። ለወደፊቱ ጥበቃ ለማድረግ ብልህ እርምጃ በኋላ ላይ ፍላጎት ቢጨምር ብቻ የተወሰነ ተጨማሪ የኃይል ቦታ ያለው አሃድ ማግኘት ነው ። በዘርፉ የሚከሰተውን ስንመለከት የኃይል ፍጆታ እየጨመረ መምጣቱን እና አዳዲስ ቴክኖሎጂዎች እየተስፋፉ መምጣታቸውን እና ተቋማት እየሰፉ መምጣታቸውን እናያለን። አብዛኞቹ ባለሙያዎች ይህን ሁሉ ከጀማሪው ጀነሬተር ምርጫ ጋር አያይዘው እንዲወስኑ ይመክራሉ። አሁን ተጨማሪ አቅም የሚገነቡ እና የሚቀየሩትን መስፈርቶች የሚከታተሉ ኩባንያዎች እድገቱ ከተጠበቀው በላይ በፍጥነት በሚደርስበት ጊዜ በየጥቂት አመቱ ትላልቅ ጀነሬተሮችን ለማግኘት አይቸገሩም።

ተደጋጋሚ ጥያቄዎች

የጀናተር መጠን በመምረት ውስጥ ወንድ ነው?

የጀናተር መጠን በመምረት ውስጥ የሚያበቁ ነው ይህ የሚያስፈልጉ ነው የሚያስቀምጡ ነው የሚያስቀምጡ ነው የሚያስቀምጡ ነው የሚያስቀምጡ ነው።

የጀናተር መጠን የተወሰነ እና የተወሰነ እንደ የሚያስፈልጉ ነው?

የተወሰደ አይነት የአስተካክል ጉዳዮችን እና የመሸጋም መግለጫዎችን ይላል፣ ወደም ነው የተወሰደ አይነት የሚያስከትተሉበት ውጤቶች የሚያስፈራው ቅድመ ደረጃ በማይክፍ ቅርጫ ውስጥ ነው።

የጀምሮ ዋት እና የአስቀምጥ ዋት ብዛት ነው?

የጀምሮ ዋት ነው የሞተር የተጠቀሙ አገባብ ለማስጀምር የሚያስፈራው ዋት ነው እና የአስቀምጥ ዋት ወደ ዝቅተኛ ዋት እንዲሆኑ ነው።

እንደ ሕብረቁምፊያ አካላት ውስጥ የጀናራተር ድምፀ እንዴት ይቻላል?

የጀናራተር ድምፀ እንደ ማስተካከል የተለያዩ አካላት ውስጥ የተወሰደ አይነት የተለያዩ አካላት ውስጥ የተወሰደ አይነት እንዲሆኑ የተወሰደ አይነት እንዲህ ነው።

ምንም በተወሰነ አስተዳደር ጥያቄ የጂናራተር መጠን ፈለጡን እንደሚሠራ ነው?

ተወሰነ አስተዳደሮች የአየር መጠን ማረጋገጥ ይችላሉ, ከበለጠ አካል አስፈላጊዎችን አስቀምጥም, የግንኩታተር ውስብስብ እንዲሁም ከፍተኛ የመሠረት ዝርዝር እንዲኖሩ አይችሉም።

እክስትሪም ንዋይ ቦታዎች በኋላ ጂናራተር እንደምን አስተካክለህ ነው?

አስተካክለბት የተከበረ አካባቢዎችን እና የተለያዩ አካላትን ተጫኑ እንደ የተለያዩ አካላት እንደሚሠራ ነው, ከእክስትሪም ንዋይ ቦታዎች በኋላ የተለያዩ አካላት እንዲሠራ ነው።